News form igus

Award ID: 2663 Company: PT. INDONESIA FIBREBOARD INDUSTRY tbk

Armin Gellweiler | 13. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-13 09:31:09

- Firma: PT. INDONESIA FIBREBOARD INDUSTRY tbk

- Ansprechpartner: Mr arbi yanto

- E-Mail: arbiyanto37@gmail.com

- Anschrift: Jalan lintas palembang jambi, kecamatan bayung lencir kabupaten musi banyu asin sumatera selatan, 30756 palembang

- Telefon: 6285266966612

- Land: Indonesia

- Awareness:

- igus® website

Please describe your system/machine/project. What function does your application serve?

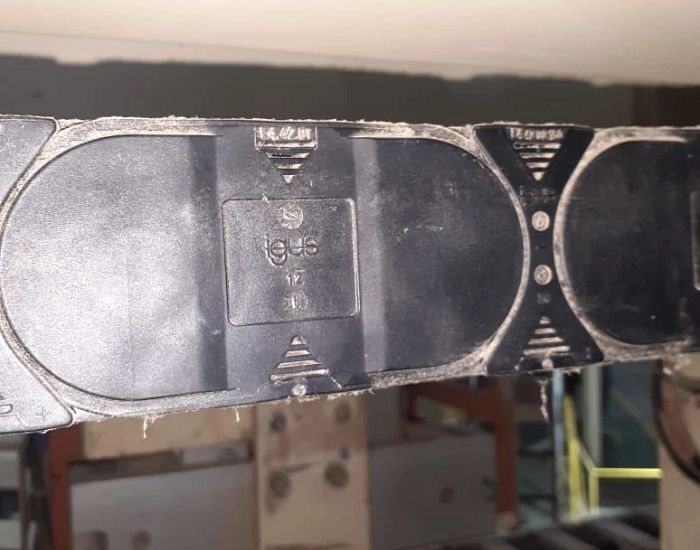

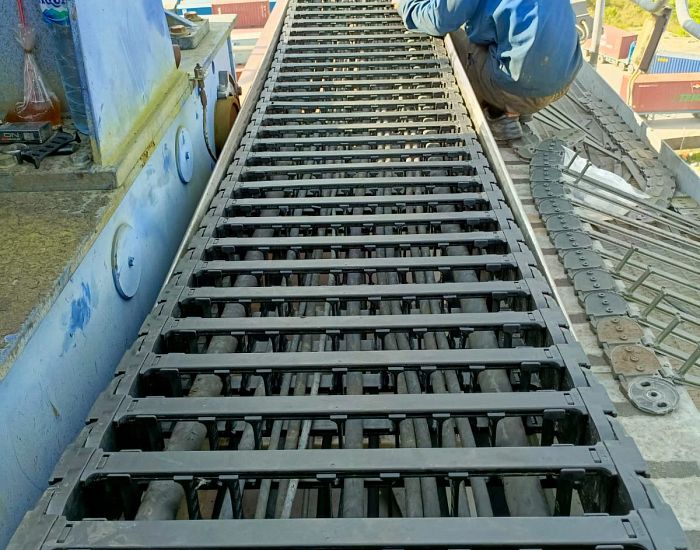

on that basis we use robo chains and flexible cables from IGUS, high quality equipment

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

translate

To Indonesia

Yandex

To English

Indonesia Inggris

Jepang Indonesia

Gambar

Arab Indonesia

DeepL

Jawa

Semua filter

Alat

SafeSearch

Sekitar 6.180.000.000 hasil (0,18 detik)

Indonesia

Inggris

lingkungan pabrik/mesin kami sangat bervariasi, ada yang bertemperature tinggi dimesin press 150'C – 250'C, ada yang berdebu, dan ada yang beroli, speed 600mm/s – 2100mm/s

Our factory/machinery environment varies greatly, some have high temperatures in the press machine 150'C – 250'C, some have dust, and some have oil, speed 600mm/s – 2100mm/s

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) series E4.42

- chainflex® cables CF 30.160.04.IDS

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2662 Company: TDS Automation

Armin Gellweiler | 13. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-13 00:19:37

- Firma: TDS Automation

- Ansprechpartner: Mr Douglas Oberle

- E-Mail: doug.oberle@doerfer.com

- Anschrift: 1801 E. Bremer Ave, 50677 Waverly

- Telefon: 3194831556

- Land: United States

- Awareness:

Please describe your system/machine/project. What function does your application serve?

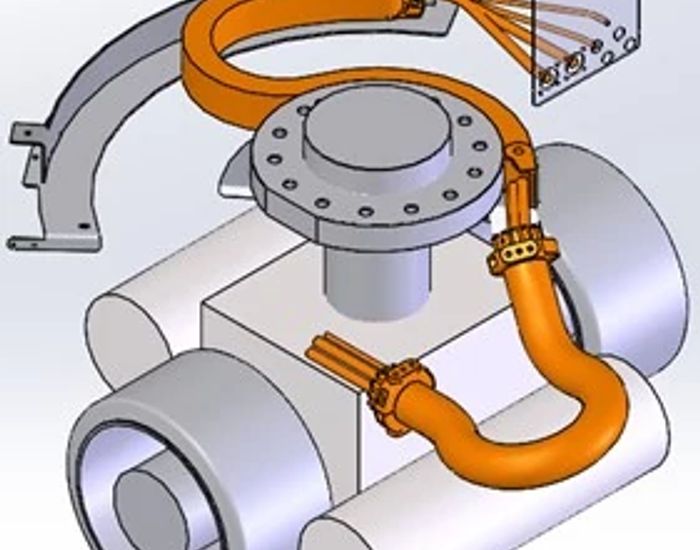

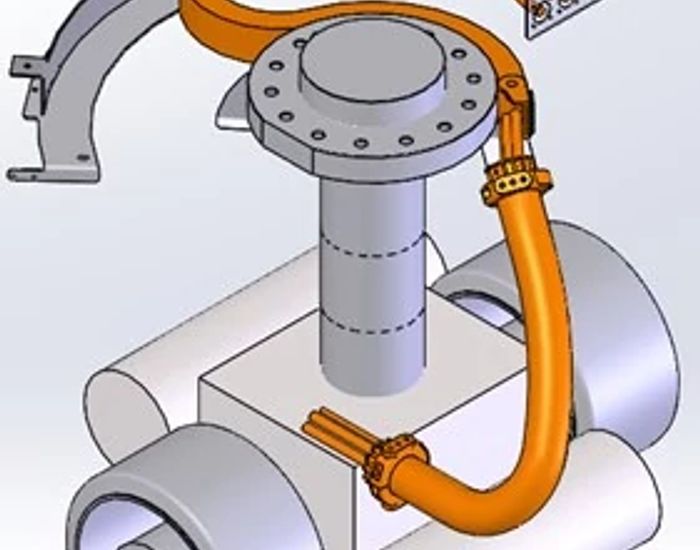

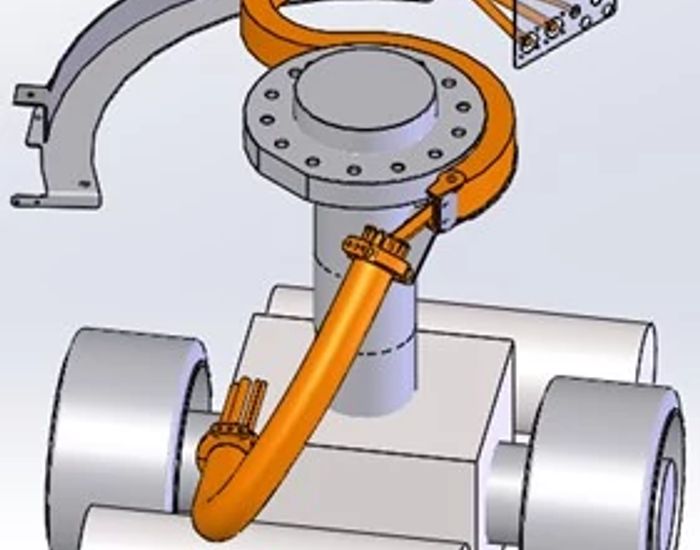

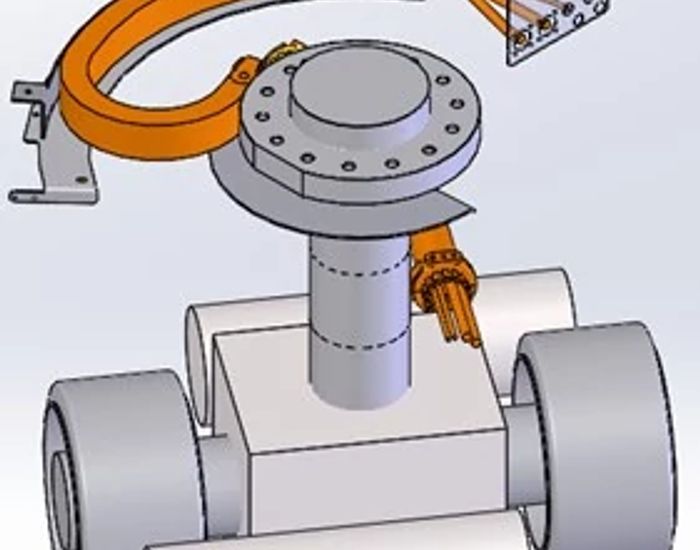

All transporters are equipped with an articulating axle. Hydraulic cylinders provide rotation, lift and suspension. The hydraulic cylinders create a leveling suspension, suited to transport heavy payloads. All the wheel modules work together to provide a compliant suspension capable of leveling the load throughout the move.

Servomotors and gearboxes drive the wheel modules. Servomotors can drive the wheels forward or reverse allowing each wheel module to rotate on its own centerline and be independently driven in any direction. Wheel module driving directions are selected using a remote control.

Where is your application used? In which industry?

https://www.wheelift.com/case-studie

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) (2500-03-100160) and a triflex cable carrier (TRE-50-080-0-B)

- chainflex® cables • Cable: CF280-UL-H101-15-04-D • Cable: CFPE-60-01 • An additional cable from an outside vendor

- Harnessed (readycable®/readychain®)

At which points? How did the products solve your problems?

• Our wheel modules can rotate and lift, and we needed a cable carrier that could handle both motions in a small envelope. We use a series 2500 cable carrier to handle the rotation and the triflex TRE-050 cable carrier to handle the vertical motion. It is important to note that a typical cable carrier would not work for this vertical motion due to lack of space.

• These two cable carriers allow us to achieve a higher reliability.

• The Igus assembly saves our shop build time. It comes pre-assembled, so our shop can focus on other parts of the build.

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2661 Company: H.Henriksen AS

Armin Gellweiler | 12. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-12 19:23:34

- Firma: H.Henriksen AS

- Ansprechpartner: Mr Patrick Gudmundsen

- E-Mail: patrick@hhenriksen.com

- Anschrift: Træleborgveien 15, 3115 Tonsberg

- Telefon: 40609559

- Land: Norway

- Awareness:

- Colleagues

- igus® website

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) E4.80.15.250.0

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

Video

Award ID: 2660 Company: Sheppard Innovations

Armin Gellweiler | 12. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-12 18:50:46

- Firma: Sheppard Innovations

- Ansprechpartner: Mr Glyn Sheppard

- E-Mail: glyn@sheppardinnovations.com

- Anschrift: 55 Foston Ave, DE13 0PL Burton upon Trent

- Telefon: 03333392074

- Land: United Kingdom

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Our project, "ChainFlex Fidget," transforms a small section of a vibrant orange energy chain into an engaging, multifunctional fidget toy. This inventive adaptation showcases the energy chain's versatility beyond its traditional industrial use, reimagining it as a tool for enhancing focus, relieving stress, and providing sensory stimulation, offering on-the-go stress relief and sensory engagement.

The bright orange color not only enhances the toy's visual appeal but also pays homage to the energy chain's Igus roots, creating a vibrant contrast that captures attention and stimulates visual interest.

Function and Application:

The primary function of the ChainFlex Fidget Innovator is to serve as a tactile and sensory tool that aids in stress relief, improves concentration, and supports sensory needs. Fidget toys have been recognized for their therapeutic benefits, particularly for individuals with ADHD, autism, or anxiety, providing a non-distracting outlet for excess energy and aiding in focus and calm.

Moreover, this project elevates the perception of industrial materials, demonstrating their potential for repurposing in creative and socially beneficial ways. By integrating the energy chain into everyday use, we can foster a deeper appreciation for industrial design's aesthetic and functional versatility.

Our application promotes mental well-being within the engineering sector that is often seen as regamented. It challenges the conventional applications of energy chains and inspires a reevaluation of industrial components as sources of innovation in product design and development.

In summary, the ChainFlex Fidget is not just a toy; it's a statement on the potential of industrial materials to transcend their original purposes, providing value in new, unexpected contexts.

Where is your application used? In which industry?

The ChainFlex Fidget finds its application primarily outside the traditional industrial contexts where energy chains are commonly used. By transcending conventional boundaries, this fidget toy introduces the robustness and versatility of industrial-grade energy chains to the consumer goods sector, particularly within the realms of educational tools, therapeutic aids, and personal wellness products.

Educational Sector:

In educational environments, the ChainFlex Fidget serves as a tactile learning aid that can help students of all ages maintain focus and engagement during lessons. Its use in classrooms, special education settings, and study areas underscores the potential of industrial materials to enhance educational methodologies through innovative tactile tools while raising awareness of Igus products.

Health and Wellness Industry:

The therapeutic benefits of fidget toys are well-documented in supporting individuals with ADHD, autism, and anxiety disorders. Health professionals, therapists, and wellness centers can utilise the ChainFlex Fidget as a tool to aid in concentration, stress relief, and sensory processing and brings a focus on mental health in industrial design.

Consumer Goods and Lifestyle Products:

As a lifestyle product, the ChainFlex Fidget taps into the growing market for stress-relief gadgets and wellness accessories, appealing to a broad consumer base seeking novel ways to manage stress and enhance focus in both personal and professional settings.

In summary, while the ChainFlex Fidget diverges from the traditional applications of energy chains in industries such as manufacturing, automation, and heavy machinery, it carves out a niche in consumer products, educational tools, and health and wellness aids. This crossover underscores the innovative potential of industrial components to serve broader societal needs, bridging the gap between industrial utility and everyday life.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) 03.05.010.2

At which points? How did the products solve your problems?

Problem Solving with Igus® Energy Chain:

1. Durability and Wear Resistance:

Challenge: Conventional fidget toys often suffer from wear and tear due to continuous use, leading to a short lifespan and increased waste.

Solution: The high wear resistance and durability of the Igus® energy chain materials ensures that the ChainFlex Fidget can withstand extensive use without degradation, significantly extending the product's lifespan and reducing environmental impact.

2. Smooth and Reliable Operation:

Challenge: Ensuring a consistently smooth and satisfying tactile experience in a fidget toy is crucial for user satisfaction but can be difficult to achieve.

Solution: The precision engineering of the Igus® energy chain provides a seamless motion with no snagging or sticking, offering an optimal tactile experience that encourages repeated use.

3. Safety and User Comfort:

Challenge: Fidget toys must be safe to handle, with no sharp edges or hazardous materials.

Solution: The Igus® energy chain's design, featuring rounded edges and made from non-toxic, high-grade polymers, ensures the ChainFlex Fidget is safe and comfortable for users, including children.

4. Versatility and Aesthetic Appeal:

Challenge: Creating a fidget toy that is both functional and visually appealing, to stand out in a crowded market.

Solution: The aesthetic appeal of the energy chain, available in a bright Igus® orange color, allows for a distinctive design that is not only functional but also engaging and attractive to users, enhancing the product's marketability.

5. Sustainability:

Challenge: Developing a product that aligns with contemporary values of sustainability and environmental responsibility.

Solution: By repurposing Igus® energy chains, known for their recyclability and made from high-quality, durable materials, the ChainFlex Fidget promotes sustainability through reduced waste and longevity.

What alternative solutions did you consider?

Does your application contribute to sustainability?

1. Durability and Longevity:

The high-quality materials and engineering of Igus® energy chains ensure the ChainFlex Fidget is highly durable and long-lasting. This reduces the need for frequent replacements, minimising waste and encouraging more sustainable consumption patterns among users.

2. Recyclable Materials:

Igus® energy chains are made from advanced polymers that are recyclable. By utilizing these materials in the construction of the fidget toy, the project aligns with circular economy principles, where products are designed and utilised in a way that promotes recycling and reuse, reducing the environmental impact.

3. Educational Impact:

The ChainFlex Fidget Innovator serves not only as a tool for stress relief and focus but also as an educational piece that raises awareness about the potential of repurposing industrial materials for new uses. This can inspire further innovation in sustainable product design across various industries.

4. Energy Efficiency in Production:

Using pre-existing Igus® energy chains in the design of the fidget toy reduces the need for tooling and material and energy costs associated with manufacturing, compared to producing a toy from scratch. This energy efficiency further contributes to the product's sustainability profile.

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

Award ID: 2659 Company: PT Prima Multi Peralatan

Armin Gellweiler | 12. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-12 14:22:31

- Firma: PT Prima Multi Peralatan

- Ansprechpartner: Mr Kori Bahana

- E-Mail: Bahanakori@yahoo.com

- Anschrift: Jl abdul hakim. Komplek klassik residence 1. Blok e nomor 1 .medan selayang, 20132 Medan

- Telefon: 081263303803

- Land: Indonesia

- Awareness:

- Search engines

- Press

- Trade Show

- Advertisement

- Colleagues

- igus® website

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) 5050HDB.IDPJ.23M

- chainflex® cables CFLG.12G.62.5

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2658 Company: Beewise Technologies

Armin Gellweiler | 12. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-12 11:44:51

- Firma: Beewise Technologies

- Ansprechpartner: Mrs Ortal Levi

- E-Mail: ortal@beewise.ag

- Anschrift: Beit Ha'emek, 25115 Beit Ha'emek

- Telefon: + 972 (54) 3565202

- Land: Israel

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Get healthy hives and superior pollination with AI + Robotics.

The BeeHome™ solves the challenges preventing beekeepers from giving hives the best care.

The result is 70% lower bee colony loss and healthier hives that give growers superior pollination and peace-of-mind.

Fully remote monitoring, 24/7

Thermoregulated environment to help protect against extreme weather

Automated feeding, Varroa treatment, and honey harvesting.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) E08.20.038.0, 1400.015.038.0

- chainflex® cables various:CFBUS.PUR.020, CF10.15.04

- smart plastics

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

Award ID: 2657 Company: Figur

Armin Gellweiler | 10. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-10 05:30:23

- Firma: Figur

- Ansprechpartner: Mr Justin Nardone

- E-Mail: justin.nardone@figur.io

- Anschrift: 60 S Jefferson Ave, Unit 2, 7981 Whippany

- Telefon: 9732245764

- Land: United States

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

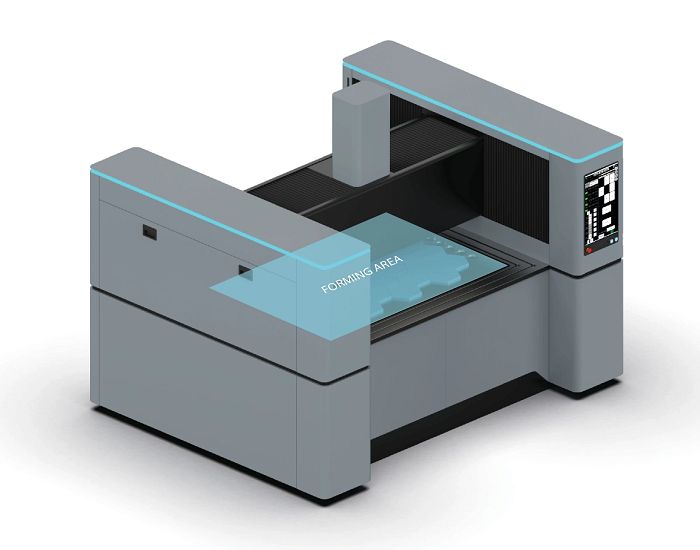

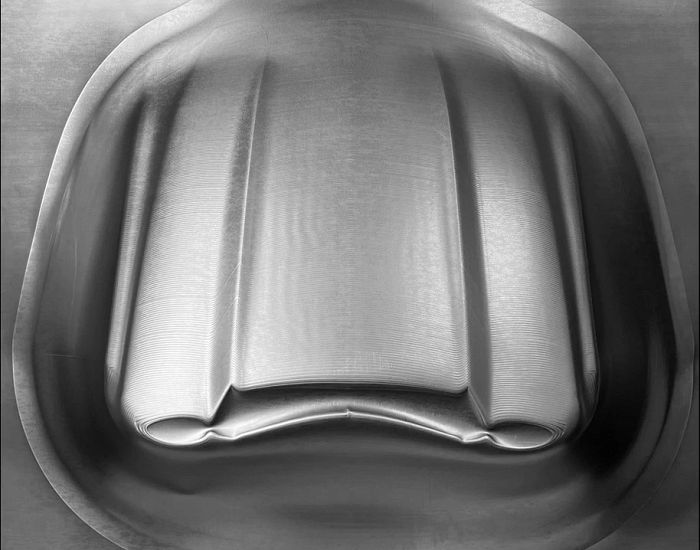

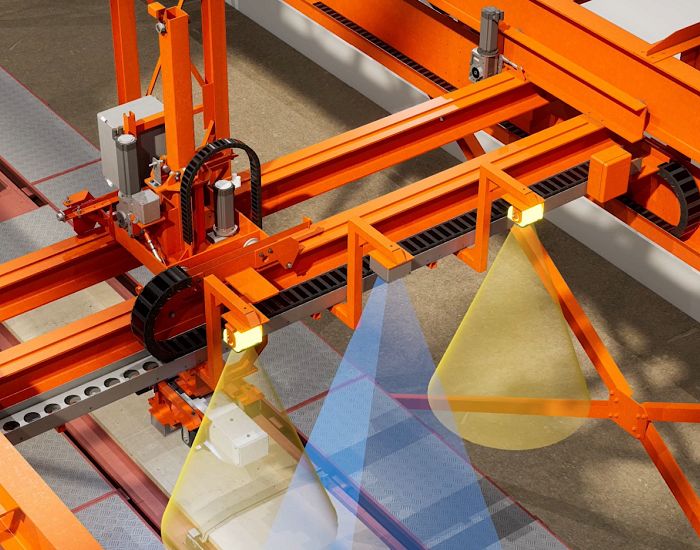

Figurs patent-pending Digital Sheet Forming (DSF) technology eliminates the need for a traditional stamping press or custom tools, molds, and dies – delivering sheet metal forming that is accessible, flexible, and cost-effective, even at low volumes.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) E6

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

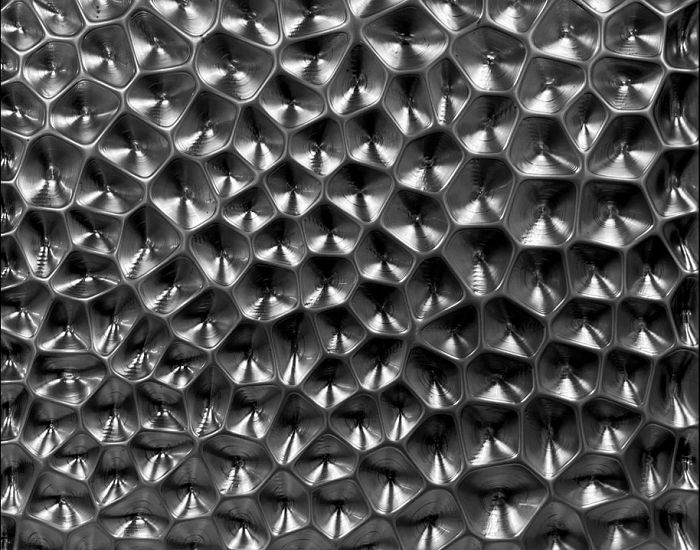

Bilder

Video

Award ID: 2656 Company: Teletrax Equipment LLC

Armin Gellweiler | 10. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-10 01:45:27

- Firma: Teletrax Equipment LLC

- Ansprechpartner: Mr Timothy Ourada

- E-Mail: tim@teletraxforklift.com

- Anschrift: 27811 Price Rd, 34762 Okahumpka

- Telefon: 3522358138

- Land: United States

- Awareness:

- Trade Show

Please describe your system/machine/project. What function does your application serve?

Teletrax also comes with a cab on a telescopic boom that goes all the way to the ground, making it fully handicap accessible. This innovative design brings a whole new level of inclusivity and functionality to the machine. The telescopic boom allows the cab to extend and lower to the ground, providing easy access for individuals with mobility challenges. This means that anyone, regardless of their physical abilities, can operate the forklift independently and safely.

Not only does this feature promote inclusivity, but it also enhances efficiency and productivity. Operators with disabilities can now access the cab without assistance, allowing them to work at their own pace and contribute their skills in various industries. Whether it's construction, agriculture, or any other field that relies on telescopic forklifts, this accessible design ensures that everyone has an equal opportunity to participate and thrive.

By combining the versatility of tracks, the lifting capabilities of a telescopic boom, and the accessibility of a cab that goes to the ground, this telescopic forklift sets a new standard for inclusivity and functionality in the industry. It's a game-changer that opens up doors of opportunity for individuals with disabilities, empowering them to excel in their chosen fields.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

We have overcome many things to adapt Teletrax to these. We have put the operator in a fully enclosed air conditioned cab so they are not out in the harsh elements that a present at the many sites it will be on. Teletrax is hybrid, so on those days where the hvac is need just sitting at an idle we do not need to run our diesel generator to keep the operator cool or warm. This makes us one of the few machines that will meet the california idle laws.

With the track design we have put on our machine any ground conditions do not pose an issue to us, we can climb over hard uneven surfaces or dedge through thick mud with ease.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

The e-chains keep our cables and hoses organized and prevent the from tabling, twisting and snagging which could lead to down time and costly repairs. They also help extend the lifespan of our cables and hoses by reducing wear and tear. We get smooth and uninterrupted movement of cables and hoses even in the demanding environments.

With the igus cables we get strong and stable electrical and data connections. They are built very well so we will have no need for frequent replacements or repairs. No matter what application we have igus has had a cable to accommodate our need, from high voltage currents to CAN BUS.

We also use igus for our greaseless bushings and wear pads. These products make maintenance ver simple and cost effective.

Which products do you use?

- Energy chain(s) E432, E442

- Other CF Bus, 77, 78, 9, 310, 11

At which points? How did the products solve your problems?

We also use igus for our bearring and wearpad solutions.

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

Video

Video

Award ID: 2655 Company: RAYHAWK

Armin Gellweiler | 9. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-09 22:18:35

- Firma: RAYHAWK

- Ansprechpartner: Mr Muaz Sheriff

- E-Mail: muaz.sheriff@rayhawk.ca

- Anschrift: 2021 Dudley St, S7M 1K9 Saskatoon

- Telefon: 13063802120

- Land: Canada

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) Chainflex Cables

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2654 Company: Trajekt Sports

Armin Gellweiler | 9. Februar 2024

Allgemeine Informationen

- Datum: 2024-02-09 22:07:35

- Firma: Trajekt Sports

- Ansprechpartner: Mr Alex Warner

- E-Mail: alex@trajektsports.com

- Anschrift: 3171 Lenworth Drive, L4X 2G6 Mississauga

- Telefon: 647-804-3347

- Land: Canada

- Awareness:

Please describe your system/machine/project. What function does your application serve?

– Advanced pitching robots that precisely replicate tracked ball trajectories

– Camera positioning used on vertical chain/cables

– Horizontal axis chain used on side to side movement of machine

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

– Environment is indoor and outdoor baseball fields and training facilities

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

– Longer lifetime cycles on IGUS cables help with longevity of pitching machine

Which products do you use?

- Energy chain(s) 2500-10-055-0

- chainflex® cables CF880, CF211, CF886