News form igus

Award ID: 2348 Company: Vulcan Inds Engg Co Pvt Ltd

Armin Gellweiler | 30. November 2023

Allgemeine Informationen

- Datum: 2023-11-30 12:07:24

- Firma: Vulcan Inds Engg Co Pvt Ltd

- Ansprechpartner: Mr Rajesh Mehta

- E-Mail: rajesh@viecl.com

- Anschrift: Survey No " 1091, Sunav – Kasor Road, PIPLAV "388460,, 388460 Anand

- Telefon: +919276094904

- Land: India

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) ECS IQU52-00212196

- chainflex® cables NA

- Harnessed (readycable®/readychain®)

- smart plastics

- Other 18840.25.200.0 Series R18840,

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2347 Company: Baumalog Sp. z o. o.

Armin Gellweiler | 29. November 2023

Allgemeine Informationen

- Datum: 2023-11-29 15:22:25

- Firma: Baumalog Sp. z o. o.

- Ansprechpartner: Pan Piotr Żołnik

- E-Mail: piotr.zolnik@baumalog.pl

- Anschrift: Ożarowska 40/42, 05-850 Duchnice

- Telefon: 600348806

- Land: Poland

- Awareness:

Please describe your system/machine/project. What function does your application serve?

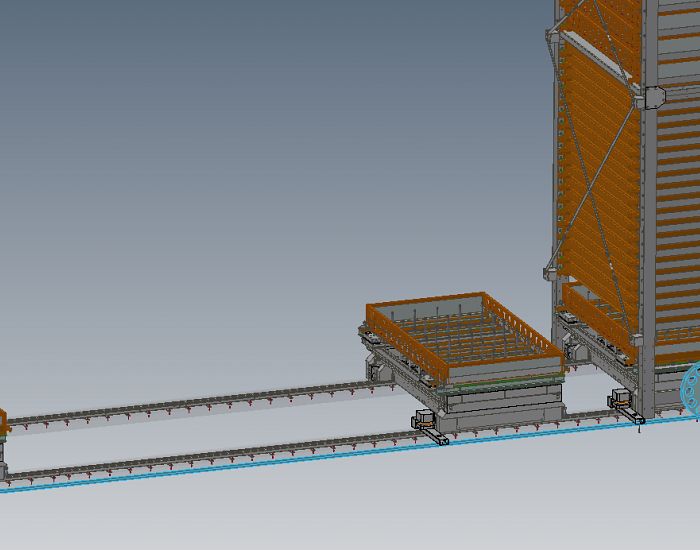

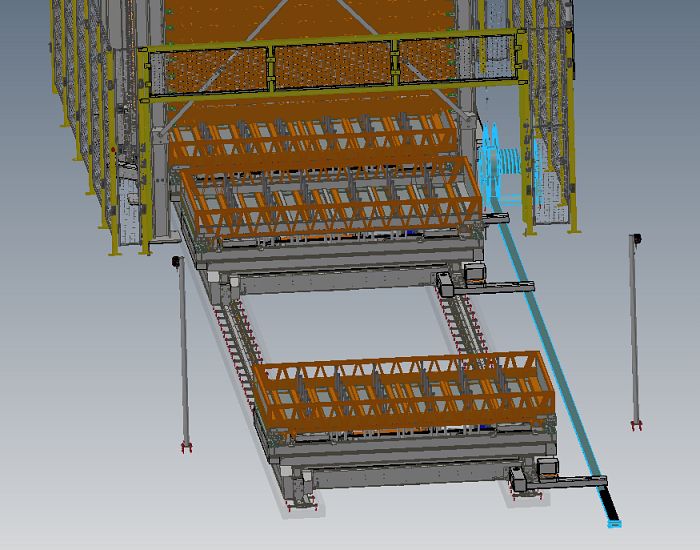

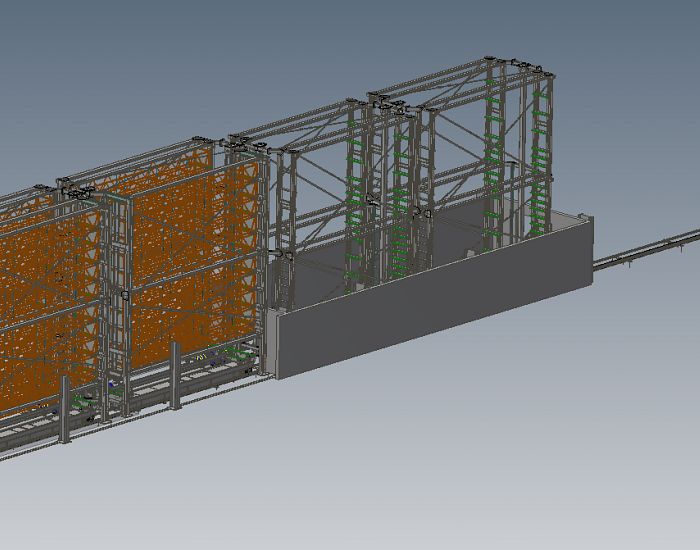

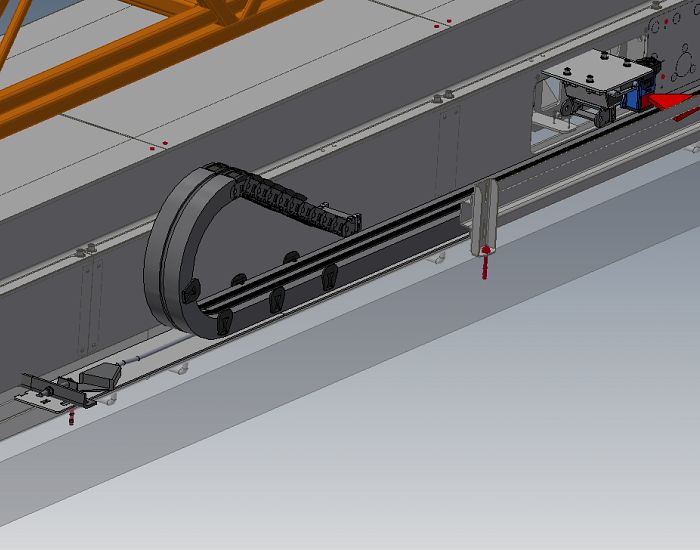

2 The system where the guide PACK.2400.07AG5.150.56000.01 allows us to drive the cart for 55 meters. Thanks to the guide line, we do not need to use the guide guides of the guide

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- –

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2346 Company: Norban Comtex Limited

Armin Gellweiler | 29. November 2023

Allgemeine Informationen

- Datum: 2023-11-29 12:43:24

- Firma: Norban Comtex Limited

- Ansprechpartner: Mr Md. Khairul Islam

- E-Mail: khairul.pr@norbangroup.com

- Anschrift: House #8/B , Gulshan#1 , 1212 Dhaka , Bangladesh

- Telefon: +8801755511684

- Land: other

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) 200.03.125

- Harnessed (readycable®/readychain®)

- smart plastics

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2345 Company: P + C2 Enterprises

Armin Gellweiler | 29. November 2023

Allgemeine Informationen

- Datum: 2023-11-29 09:05:26

- Firma: P + C2 Enterprises

- Ansprechpartner: Mr Pankaj Kumar Chuneja

- E-Mail: sales.pplusc2@gmail.com

- Anschrift: Bhiwadi , 301019 Bhiwadi

- Telefon: 8058779964

- Land: India

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s)

- Harnessed (readycable®/readychain®)

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2344 Company: gurukrupa forklift services

Armin Gellweiler | 29. November 2023

Allgemeine Informationen

- Datum: 2023-11-29 07:15:09

- Firma: gurukrupa forklift services

- Ansprechpartner: Mr vinayaka vinay

- E-Mail: gurukrupa.vinayaka@gmail.com

- Anschrift: K. NO. 4/36, BASHETTIHALLIDODDABALLAPURA, 561203 Bengaluru (Bangalore) Rural

- Telefon: 09886712579

- Land: India

- Awareness:

- igus® website

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

This is good news but not a signal to let up; it’s just a signal that we are on the right track and need to continue. We are still looking at ongoing serious weather events; but we aren’t looking at an oncoming catastrophe.

The article in the N.Y. Times said we’re on Second Base on handling the climate. The US is getting rid of coal fired power plants and replacing them with cleaners sources. We need to continue on the path of solar, wind and nuclear power and the electrification of vehicles, the article said.

This is the best news we’ve heard for quite a while and gives credence to the idea that we can do something about climate change. At least we can reduce the added CO2 that we have been putting into the atmosphere. And the increase in temperatures that was expected has at least lessened. This is proof that CO2 emissions do indeed make for a warmer climate and reducing CO2 emissions reverses the trend. If we needed empirical proof, this is it.

Worldwide conditions affect local conditions, so this is good news for both. It’s good to know that reducing CO2 emissions is working and reinforces the feeling that we can indeed turn things around.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) series E4.1/R4.1

- chainflex® cables CF885

- Harnessed (readycable®/readychain®)

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2343 Company: ACG PAM PHARMA TECHNOLOGIES

Armin Gellweiler | 28. November 2023

Allgemeine Informationen

- Datum: 2023-11-28 18:37:40

- Firma: ACG PAM PHARMA TECHNOLOGIES

- Ansprechpartner: Mr Baktawar Shaikh

- E-Mail: baktawar.shaikh@acg-world.com

- Anschrift: MAVAL, 411018 PUNE

- Telefon: 09923587013

- Land: India

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Supply of completely tested equipments which provide better performance and reliability.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) cable routing application

- chainflex® cables for communication.

- Harnessed (readycable®/readychain®)

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2342 Company: Macrodyne Technologies Inc

Armin Gellweiler | 28. November 2023

Allgemeine Informationen

- Datum: 2023-11-28 18:11:17

- Firma: Macrodyne Technologies Inc

- Ansprechpartner: Mr Kevyan Kashvandi

- E-Mail: kkashvandi@macrodynepress.com

- Anschrift: 311 Connie Crescent, L4K 5R2 Concord

- Telefon: (905) 669-2253

- Land: Canada

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Challenges included going through Temperature ranges from 30 to 200C, Oil, Dust, Greasy Env, Hot Steam and Heavy Duty Fill (Electrical and Hydraulics hoses) package, weight.

We needed to be able to support a weight of 150 lb. The travel distances ranged between 5 feet to 12 feet.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

There may be some cost reduction related to reduced maintenance, as the YE chain has performed without incident thus far.

Which products do you use?

- Energy chain(s) YE.56

At which points? How did the products solve your problems?

This was a required product that fit the application perfectly. Keeping minimal weight was a problem that needed solving and because the YE chain is also made of plastic, the weight was kept to a minimum, compared to its steel competitors.

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2341 Company: TRIVEDI TECTONICS

Armin Gellweiler | 28. November 2023

Allgemeine Informationen

- Datum: 2023-11-28 17:36:20

- Firma: TRIVEDI TECTONICS

- Ansprechpartner: Mr SANJAY SAXENA

- E-Mail: sanjay@trivedigroup.com

- Anschrift: 415, Moraiya Industrial Area, Sarkhej Bavla Highway, Moraiya, 382213 Ahmedabad

- Telefon: +919978442016

- Land: India

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Making sculptures, statues, and all kind of stone carvings.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s)

- chainflex® cables

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2340 Company: prilla mill

Armin Gellweiler | 28. November 2023

Allgemeine Informationen

- Datum: 2023-11-28 15:06:35

- Firma: prilla mill

- Ansprechpartner: Mr satpal singh

- E-Mail: satpal@prilla.co.za

- Anschrift: 227 bhambatha road, 3201 pietermaritzburg

- Telefon: 0333977800

- Land: South Africa

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s)

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Award ID: 2339 Company: WAAM3D Limited

Armin Gellweiler | 28. November 2023

Allgemeine Informationen

- Datum: 2023-11-28 13:01:54

- Firma: WAAM3D Limited

- Ansprechpartner: Mr Filomeno Martina

- E-Mail: filo@waam3d.com

- Anschrift: 5 Thornton Chase, MK146FD Milton Keynes

- Telefon: 01908101030

- Land: United Kingdom

- Awareness:

Please describe your system/machine/project. What function does your application serve?

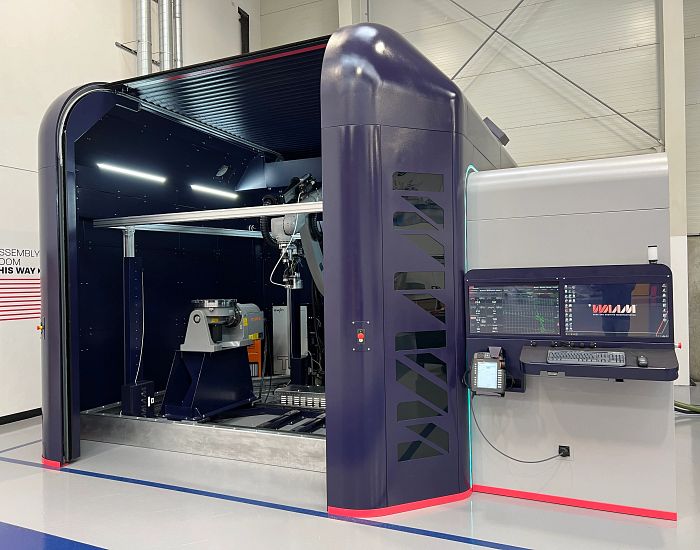

Within large-scale metal AM, WAAM3D provides the only end-to-end software solution covering computer aided manufacturing, to machine and process control, to post-build data analytics.

RoboWAAM, their award-winning state-of-the-art large format printer, has the largest number of sensors and the most advanced process monitoring and control in the industry. It goes above and beyond what standards and certification bodies demand, providing the highest level of confidence over the quality of the output produced.

WAAM3D also owns a patent on the in-process application of mechanical deformation, to achieve forged level of mechanical properties within additively made structures. This is by far the most robust method to enable like-for-like transition from incumbent wasteful manufacturing processes to the more modern additive approach.

WAAM3D has received awards for Aerospace Application of the Year in 2019, Best 3D Printing Hardware in 2022, and recently ATI Breakthrough award for the start-up company with the most potential to impact aerospace and to support the journey to net zero 2050 for commercial flight.

Where is your application used? In which industry?

As Carbon Fibre Reinforced Polymers use grew on modern aircrafts, so did the amount of titanium. In weight, Boeing’s 747 had 1% of CFRP and 4% of titanium; Airbus’ A350 53% and 14%, respectively. This explains why, in terms of number of demonstrators built, those in titanium alloys have received the largest interest, especially in Ti-6Al-4V (Ti64). This is thanks to the alloy’s cost, the difficulty in processing it (either when forged or machined), and the way parts are made traditionally, with huge fractions turned into low value swarf. Hence, the rise of an urgent need for an alternative manufacturing process.

The potential can be measured in terms of its current and forecasted size. Today, the global AM market is worth £15bn, and is expected to grow at 20.8% to reach over £60bn by 2030. Crucially, this figure represents only metal AM applications, and excludes the revenues associated with metal AM hardware, materials or software. Market revenues are estimated at $18b, $3b, and $11b for hardware, materials and services, respectively, by 2030. With specific regards to WAAM, cumulative machines sold forecasts 3,501 units. WAAM3D has the most advanced kit on the market, and is extremely well placed to seize this opportunity.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

containment of highly critical equipment e.g. fibre optics

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) TR.RSE.70