News form igus

Award ID: 2375 Company: 华润电力(温州)有限公司

Armin Gellweiler | 29. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-29 03:57:32

- Firma: 华润电力(温州)有限公司

- Ansprechpartner: 先生/ 时 艾

- E-Mail: 1069774181@qq.com

- Anschrift: 浙江省温州市龙港市, 325802 温州市

- Telefon: 18285861001

- Land: China

- Awareness:

- Igus Web Site

Please describe your system/machine/project. What function does your application serve?

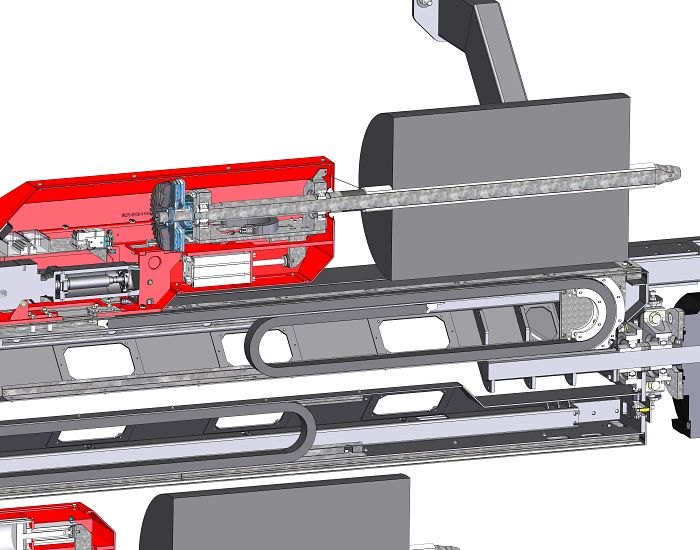

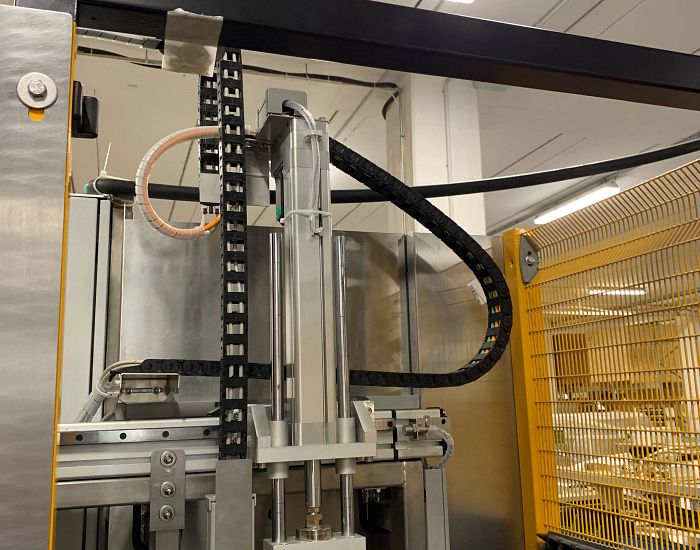

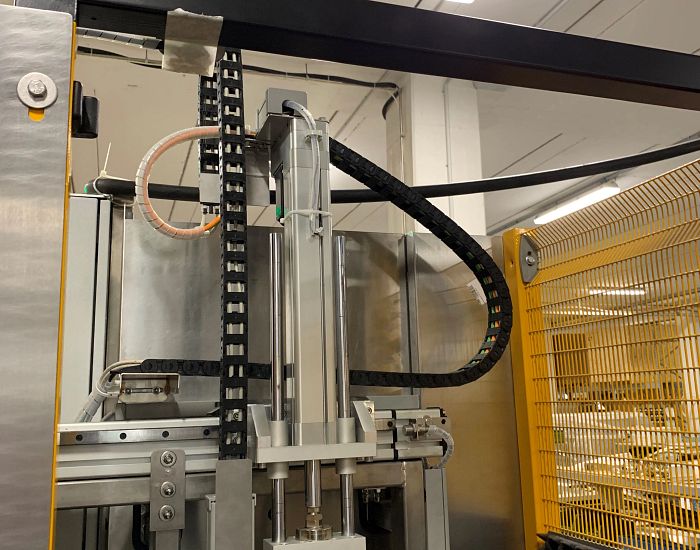

2. not optimized before the bucket wheel stacker reclaimer hopper top rotary cable fixed bracket structure design is unreasonable, the cable can not be large arc bending, cable twisting after frequent force, most of the cable cracking, cable frequent short circuit, broken strands and other phenomena.

Through the optimization of the design of fixed cable bracket, configuration of rotary winding drag chain and replacement of CF300, CF10 series of super-soft bend-resistant cables after the cable failure rate to reduce the failure rate of the equipment to reduce the failure rate, and effectively improve the reliability of equipment operation.

Where is your application used? In which industry?

2. Power plant, harbor and other industries.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

2. There is error in the height measurement of rotary drag chain before transformation, the height of rotary drag chain after installation is too high, and the gap between cable drag chain installation cables is set unreasonably. The original bucket wheel stacker and reclaimer can be tilted up to a height of about 10°, but after the installation of the drag chain, it can only be lifted up to about 7.5° after the trial run, and then it touches the rotary drag chain, which restricts the angle of tilting up, and seriously affects the operation of the stacking and reclaiming of coal, and then after the on-site discussion, the plan of removing the joint piece to reduce the height of the drag chain was determined, and the interval gap between the drag chain of the cable was adjusted to optimize and ultimately meet the use of the demand.

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

2. through the transformation of the reliability of equipment operation has been significantly improved, did not occur due to cable failure caused by equipment shutdown and emergency repair events, defects from the most 8 per month down to less than

3. . No cable defects, effectively avoiding the long failure time of the bucket wheel affecting the coal \unloading problem, providing a guarantee for the operation of the unit, thus indirectly achieving cost optimization.

Which products do you use?

- Drag chain RBR heavy duty slewing/E4.80

- chainflex® high flexible cable CF300, CF10 and other series power cables, control, computer cables

At which points? How did the products solve your problems?

2. through the optimization of the original cable support structure at the rotary, the use of optimized drag chain bending radius, toughness and combined with super-soft bend-resistant cable with good insulation and flexibility, and according to the cable trajectory and characteristics, to effectively avoid long-term bending and torsion due to the bucket wheel stacker reclaimer hopper at the top of the rotary cable long-term bending and torsion of the risk of damage after the stress of the broken core, the equipment has been running without defects, and at the same time, for the later inspection, maintenance of the equipment to provideConvenience.

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

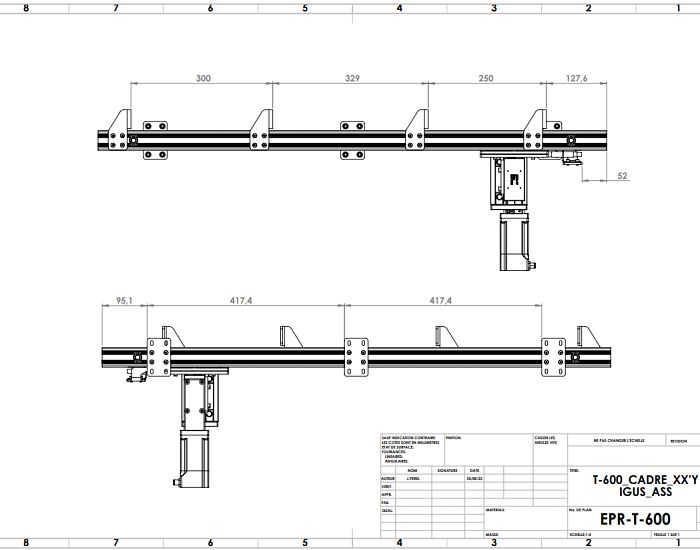

Award ID: 2374 Company: A3D Additive Printer sl

Armin Gellweiler | 26. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-26 13:47:30

- Firma: A3D Additive Printer sl

- Ansprechpartner: Sr. Álvaro Roca de Togores

- E-Mail: aroca@a3dprinter.es

- Anschrift: Valgrande 25 nave 13, 28108 Alcobendas

- Telefon: 628719503

- Land: Spain

- Awareness:

- Known

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

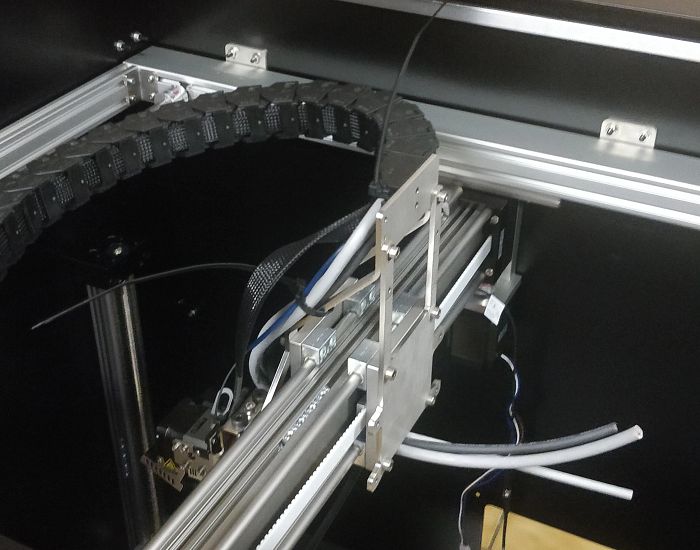

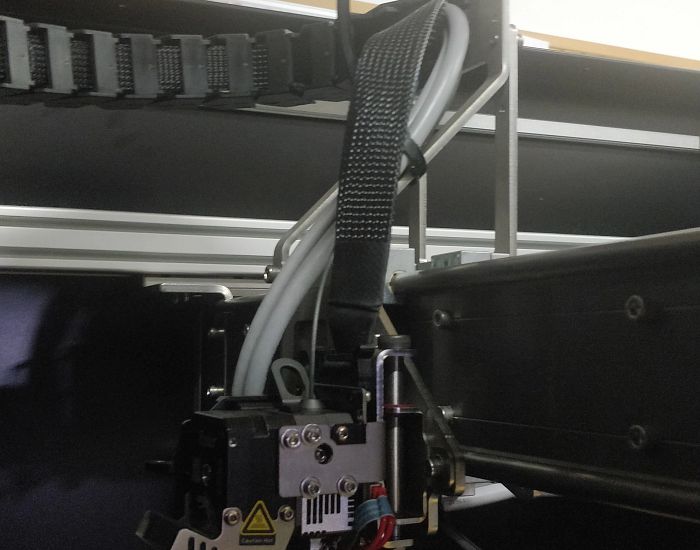

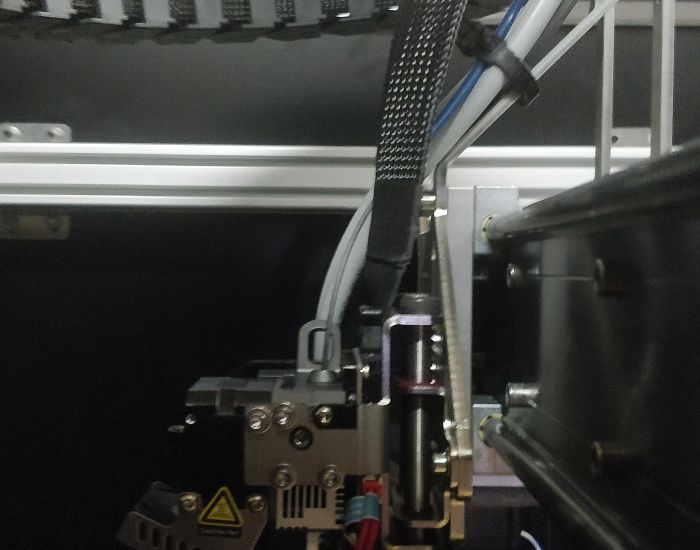

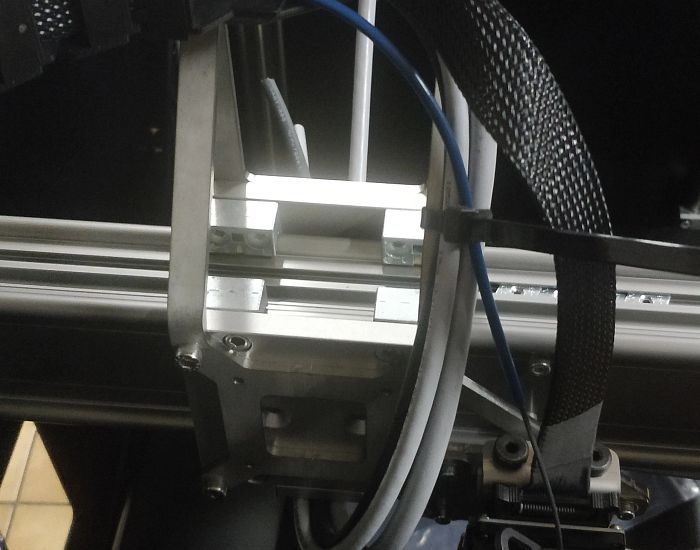

Which products do you use?

- ECS IQU52-00205320

ECS energy chain(s)/00205320

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

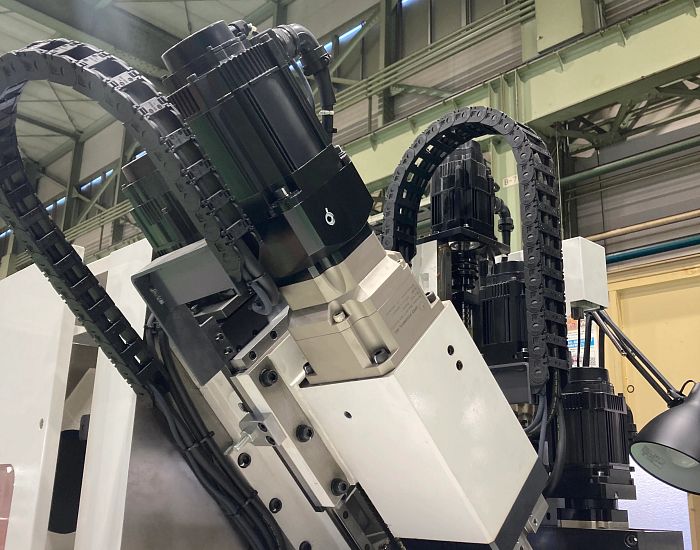

Award ID: 2373 Company: Asahi-Seiki Manufacturing Co., Ltd.

Armin Gellweiler | 25. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-25 06:02:46

- Firma: Asahi-Seiki Manufacturing Co., Ltd.

- Ansprechpartner: Mr(男性) 高志 野島

- E-Mail: takashi-nojima@asahiseiki-mfg.co.jp

- Anschrift: 旭前町新田洞5050-1, 愛知県尾張旭市

- Telefon: 0561-52-5322

- Land: Japan

- Awareness:

- Other

- .

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

- Space saving

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy Chain E2/

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

- Other

.

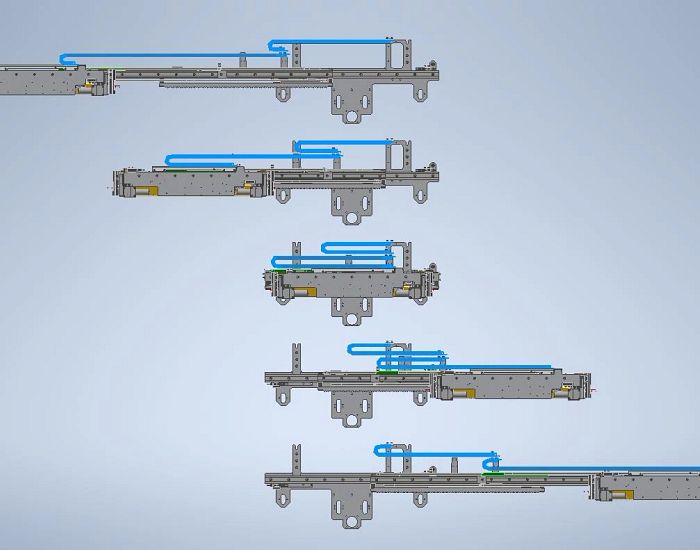

Bilder

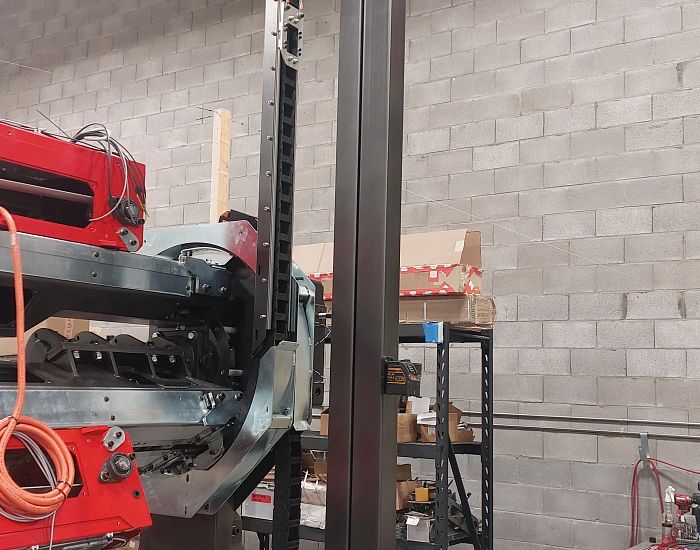

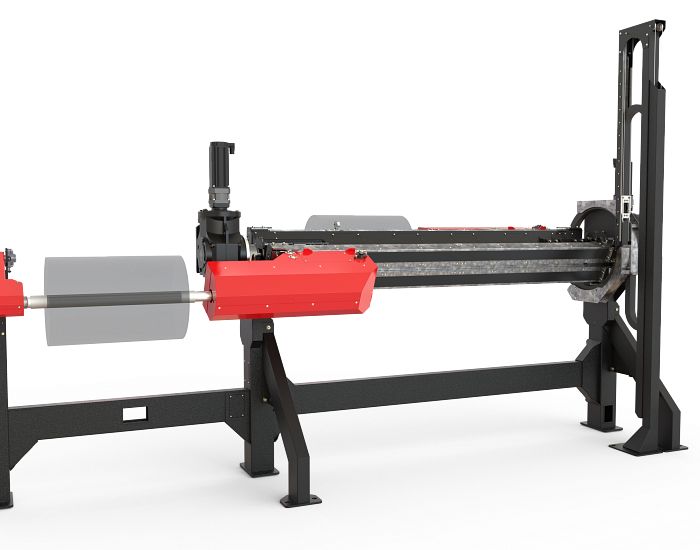

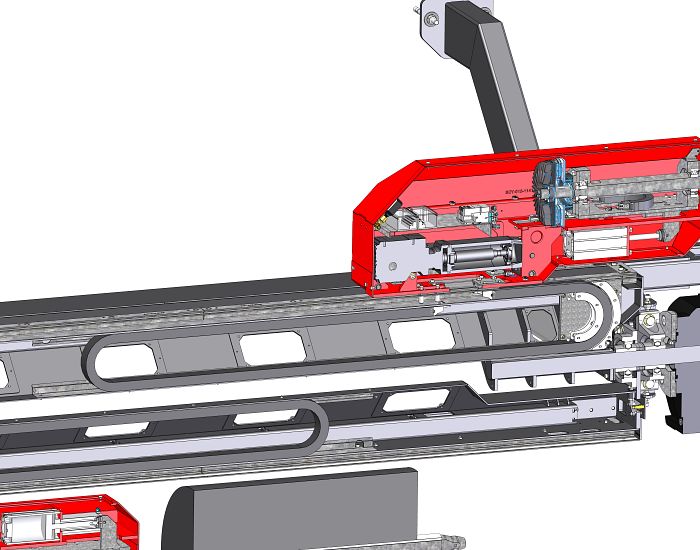

Award ID: 2372 Company: Inogec

Armin Gellweiler | 23. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-23 16:27:14

- Firma: Inogec

- Ansprechpartner: Monsieur Samuel Leblanc

- E-Mail: samuel.leblanc@inogec.com

- Anschrift: 490 rue Léger, J1L 1Y5 Sherbrooke

- Telefon: 8197919988

- Land: Canada

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

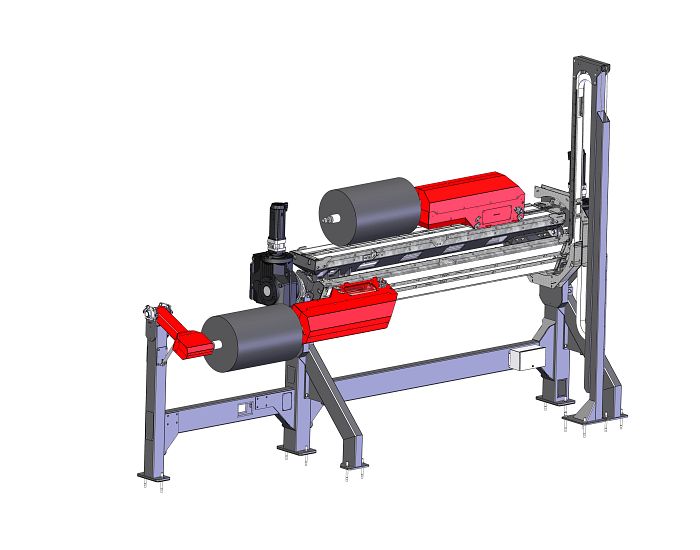

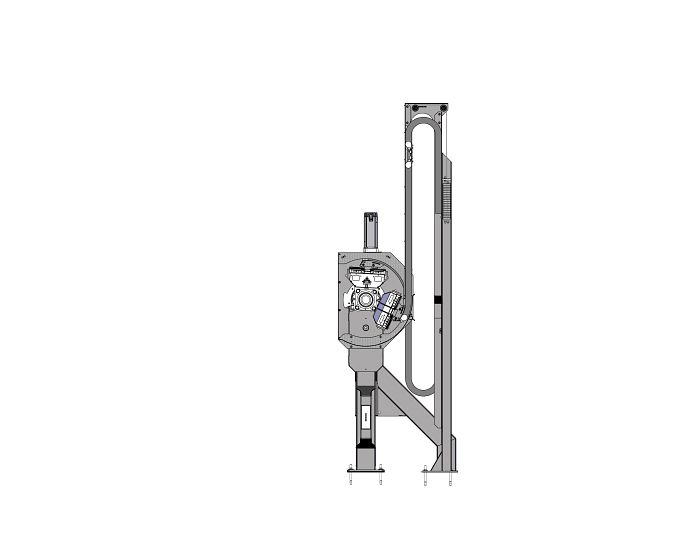

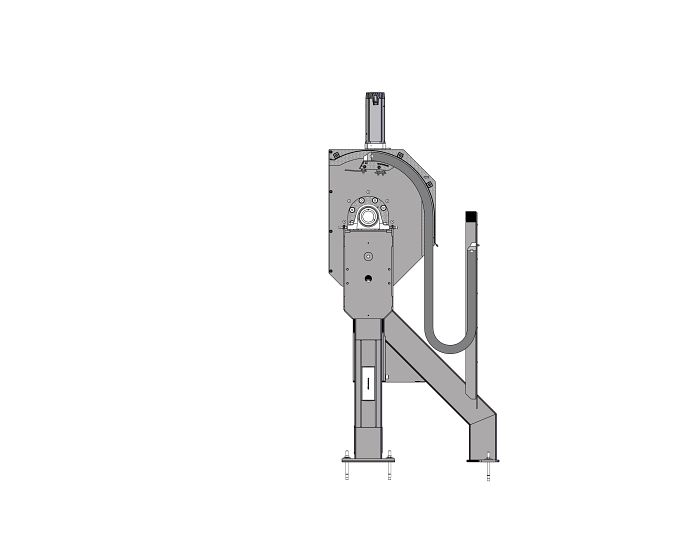

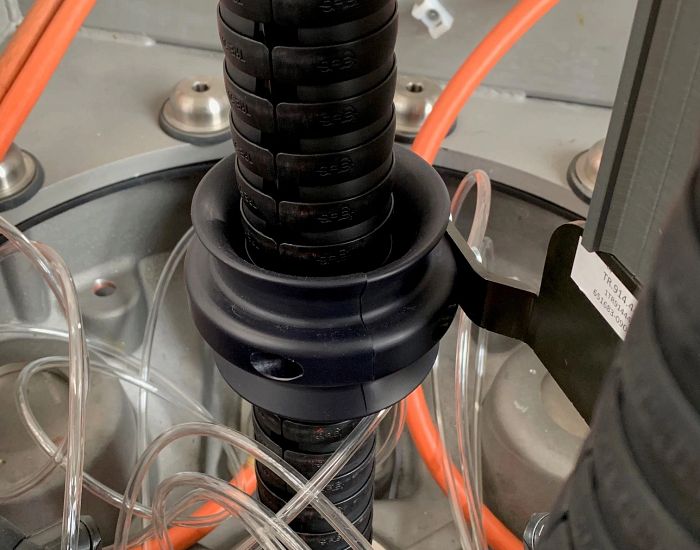

The second application involves bringing the cables of the two rotation axes to the machines fixed frame. As two separate roller supports use the same axis of rotation, a technical challenge lay in the electrical and pneumatic power supply to these two supports.

Which products do you use?

- Cable chain(s) 2400-03-075NC-2020 and 3400-050-150_450 (double radius of curvature)

At which points? How did the products solve your problems?

The second location is at the end of the rotation axes, around the same rotation axis. We used standard chains with a bending radius on both sides to realize a rotating chain concept. See further photos.

What alternative solutions did you consider?

In the second case, we would have had to use a slip ring, or the Igus product designed specifically for this type of application. In both cases, the cost of the solution would have been much higher, and difficult to integrate into the design. Once again, we would have lost floor space.

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2371 Company: MPL TECHMA Sp. z o.o.

Armin Gellweiler | 21. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-21 15:54:24

- Firma: MPL TECHMA Sp. z o.o.

- Ansprechpartner: Pani Monika Nienadowska

- E-Mail: monika.nienadowska@mpltechma.pl

- Anschrift: Telewizyjna 22, 80-209 Chwaszczyno

- Telefon: 531257581

- Land: Poland

- Awareness:

- Collaborators

- igus® website

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

1. Vibration and Load: Due to the continuous movement of dozens of carts in the warehouse structure in the warehouse, vibration and loading are likely to occur, which required the guides to be properly designed to withstand these conditions.

2 Contamination: The warehouse environment can be susceptible to contaminants such as dust, dirt and even potential chemicals. The slides must withstand these elements to ensure reliable operation. Technical Challenges: 1. double-sided extension: Implementing an extension mechanism that operates bilaterally, that is, in both directions, is a design challenge. Slides must be designed to allow stable and even extension in both directions. 2 Double the depth of extension in each direction: The need to ensure that slides allow for double extension depth in both directions, which can increase loading and affect durability. Guides must be robust enough to handle this extended range of motion

Adaptation to Conditions:

To adapt to these conditions, the design had to take into account:

– Environmental resilience: Selecting E2.10 guides that provide cable safety, flexibility, and reliability in signal and power transmission.

– Proper cable organization: Using special Igus cables with separators every 2nd link to ensure proper organization of cables in the guides.

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- e-chain(s) E2.10.30.018.0

At which points? How did the products solve your problems?

Method of Problem Solving: Guide Selection Criteria: E2.10 guides were chosen because of the need for self-supporting power and signal guidance over a large operating range (1410 mm). Their flexibility, ability to maintain maximum speed (1.2 m/s at the last end of the guide) and ability to bend with a radius of R 20 allowed for trouble-free transmission of signals and power. Drawings/3D projections and Fixtures: Detailed drawings and 3D projections of the guides in the structure allowed for proper design of the mounts, which was crucial for the stability of cable routing at each end of the guide.

Working Ranges and Cable Arrangement: The E2.10 guides enabled operation over a wide operating range, and cable routing using 4 Igus-branded cables and 3 separators every 2nd link in both guides ensured proper cable organization.

The use of E2.10 series slides was crucial in enabling the safe and reliable transmission of power and signals over a large operating range in the telescopic Shuttle mechanism. Their flexibility, resistance to high speeds and bending capability allowed for an effective technical solution, minimizing power and signal transmission problems in this advanced logistics system.

What alternative solutions did you consider?

Does your application contribute to sustainability?

Energy Efficiency:

Optimization of Power Transmission: Using the right slides helps power transmission efficiently, minimizing energy loss in the transmission process. This can help increase the energy efficiency of the system.

Efficiency and Failure Reduction:

Minimizing Cable Damage: The E2.10 series guides can reduce the risk of damage and interruptions in signal and power transmission. This contributes to system efficiency and reduced failures, which reduces the need for repairs and component replacement, resulting in less resource consumption.

Long System Life:

Long Life of Guides: E2.10 guides are resistant to environmental conditions (such as pollution or vibration), and can contribute to the long-term durability of the system, reducing the need for frequent replacement or maintenance. Adapting to Project Needs: The selection of slides was deliberate and tailored to the specific needs of the project, indicating a sustainable technological aspect by choosing the optimal components suitable for the application.

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2370 Company: Sumitomo Demag

Armin Gellweiler | 20. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-20 12:51:18

- Firma: Sumitomo Demag

- Ansprechpartner: Mr Tobias Beckstein

- E-Mail: tobias.beckstein@shi-g.com

- Anschrift: Altdorfer Straße 15, 90571 Schwaig

- Telefon: +49 173 3029498

- Land: Germany

- Awareness:

- Advertisement

Please describe your system/machine/project. What function does your application serve?

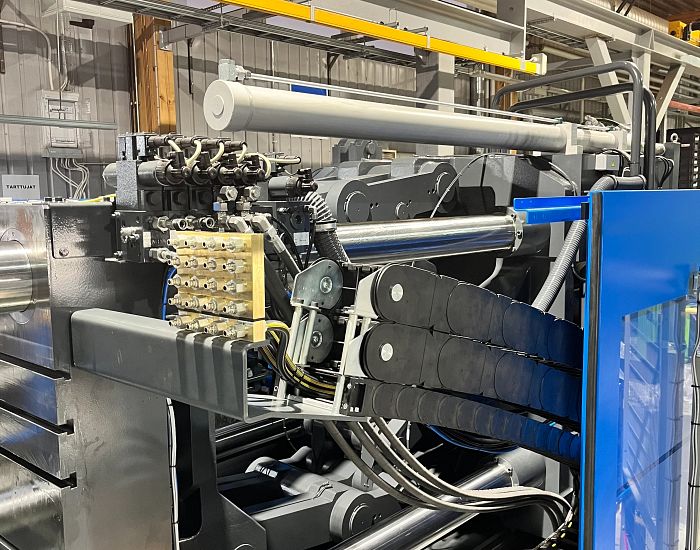

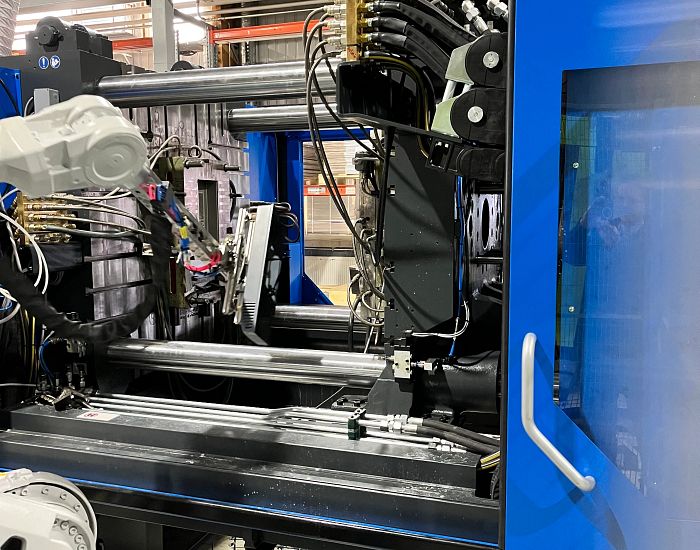

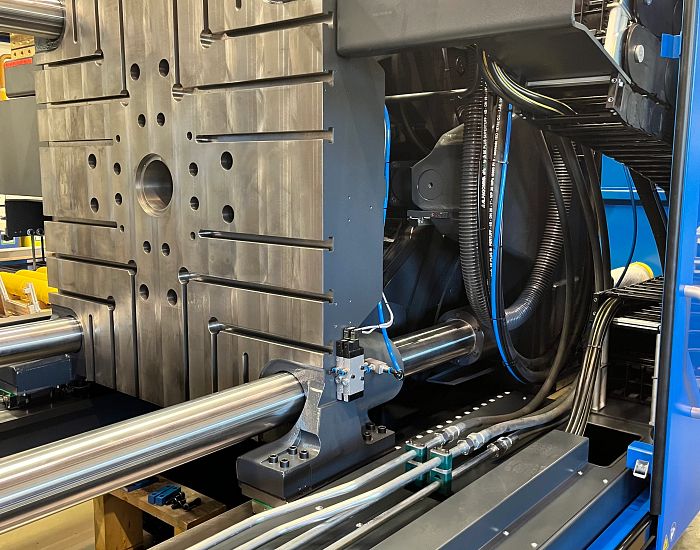

They are a 650 tonne injection moulding machine and a 1000 tonne injection moulding machine.

This is a complex application for high-temperature water up to 140° with special hoses. These hoses are very sensitive to friction, and we have worked with IGUS to find a solution to ensure this.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

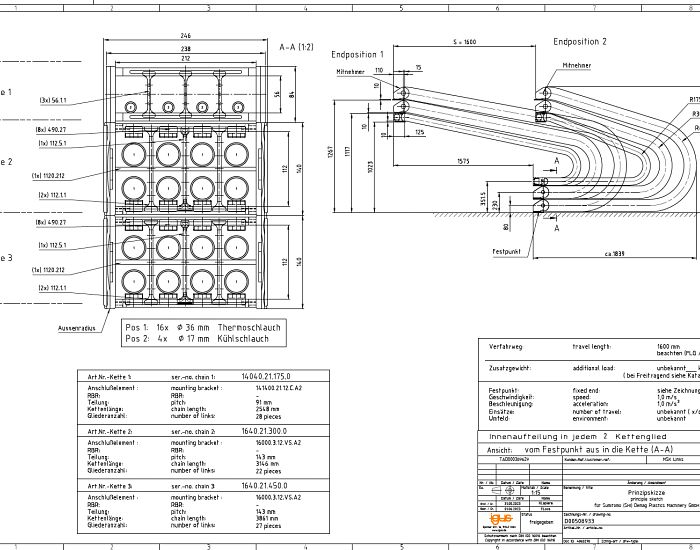

Installation of a mould temperature control with two temperature zones. A total of 32 tempering circuits with 140° tubing and 8 tempering circuits up to 95° were installed in the machine. The special requirement here was that the high-temperature hoses should not wear out due to friction. The solution was three interlocking e-chains. Two chains were used for the 140° tubing and another chain for 95°.

Due to the high dynamics of an injection moulding machine, it is very important to avoid damage to the high-temperature hoses. In addition to the safety risk of defective hoses, the costs of the tubing are also very high.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Energy chain(s) 14040.21.175.0 + 2x 1640.21.450.0

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2369 Company: Imball srl

Armin Gellweiler | 19. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-19 18:38:44

- Firma: Imball srl

- Ansprechpartner: Sig. Mirco Muzzi

- E-Mail: mirco.muzzi@imball.it

- Anschrift: Via Ca' de Testi 16/3, 40037 Sasso Marconi(BO)

- Telefon: 39051842154

- Land: Italy

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- i system for triflex tre.60 energy chains

- chainflex® cables

- Other RSE system

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

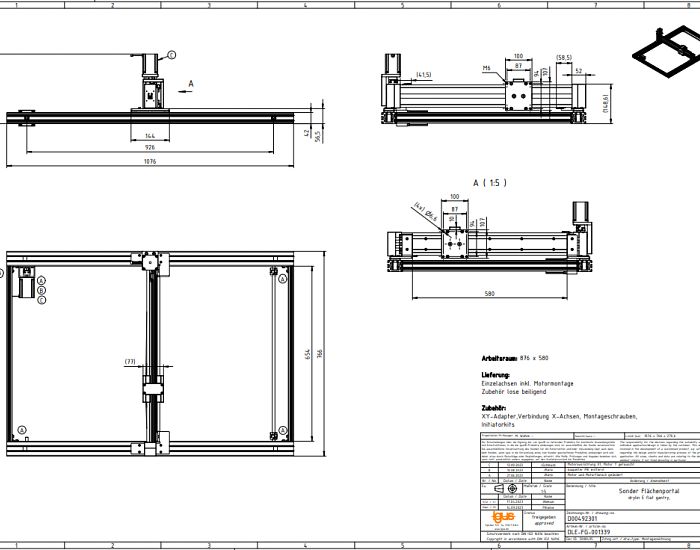

Award ID: 2368 Company: EPEIRE 3D

Armin Gellweiler | 19. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-19 16:05:19

- Firma: EPEIRE 3D

- Ansprechpartner: Monsieur Jérémy Pérel

- E-Mail: jperel@epeire3d.com

- Anschrift: 143 Ter Rue Pasteur, 59320 Haubourdin

- Telefon: 648294078

- Land: France

- Awareness:

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

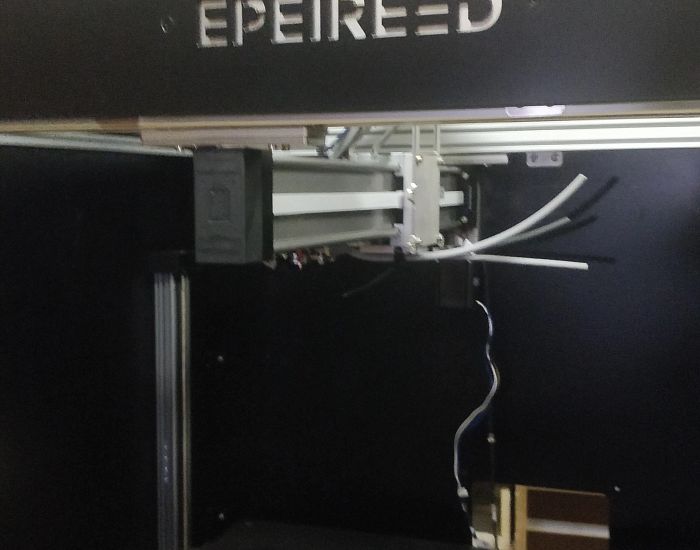

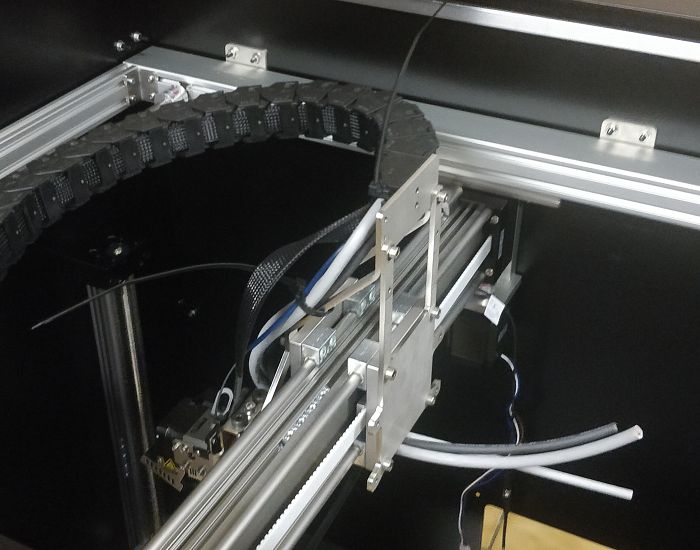

Which products do you use?

- Cable chain(s) E2.26

- chainflex® cables CF211.PUR.05.04.02

- Smart plastics

- Other DLE-FG -001339

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Video

Video

Video

Award ID: 2367 Company: Teknox srl

Armin Gellweiler | 19. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-19 10:26:33

- Firma: Teknox srl

- Ansprechpartner: Sig. Andrea Marcuzzi

- E-Mail: andrea.marcuzzi@teknox.net

- Anschrift: Via Mori 6, 40054 Prunaro di Budrio(BO)

- Telefon: 39051800862

- Land: Italy

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- i system for energy chains B15i.038.038.0

At which points? How did the products solve your problems?

What alternative solutions did you consider?

Does your application contribute to sustainability?

Was there co-operation with igus®? If so, how was it?

How did you become aware of the vector competition?

Bilder

Award ID: 2366 Company: Cimolai Technology

Armin Gellweiler | 19. Dezember 2023

Allgemeine Informationen

- Datum: 2023-12-19 09:59:14

- Firma: Cimolai Technology

- Ansprechpartner: Sig. Donato Cecchin

- E-Mail: donato.cecchin@cimolai.tech

- Anschrift: Via dell'Industria e dell'artigianato, 17, 35010 Carmignano di Brenta

- Telefon: 390499404539

- Land: Italy

- Awareness:

- Altro

Please describe your system/machine/project. What function does your application serve?

Now Cimolai Technology has created a modern version of it: the newly opened interactive experience at Rockefeller Center called ”The Beam” allows visitors to recreate the famous photo.

Located on the 69th floor of the Top of the Rock, the steel beam rises 12 feet above the Observation Deck, then makes a 180-degree turn and takes the photo with the view of Central Park and Manhattan.

Cimolai Technology chose igus products to guide the hoses in a vertical movement and in rotation: inside the telescopic column there are 2 energy chain series 2700 and 2600, one in hanging installation and one in standing installation in opposite solution; on the base there is a E4.1 chain in rotation installation. Together with the chain Cimolai used our chainflex cable in TPE insulation, which is characterised by its resistance to low temperatures.

Where is your application used? In which industry?

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- sistema/i per catene portacavi

- cavi chainflex®