News form igus

Award ID: 2481 Company: Serve IDP

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 17:15:37

- Firma: Serve IDP

- Ansprechpartner: Pan Darek Parczewski

- E-Mail: tech@e-serve.pl

- Anschrift: Szczęśliwa 28, 05-500 Wólka Kozodawska

- Telefon: 727035067

- Land: Poland

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Zero Gravity Workstation for long-term computer work. ZeroG The external monitors are suspended from a structure above the workstation, which makes it necessary to run a lot of cables. Since part of the workstation is mobile during use, the cables should be clipped together to avoid damage and look aesthetically pleasing. So the application acts as a cable route organizer.onitory zewnętrzne są podwieszone na konstrukcji ponad stolikiem roboczym, co powoduje konieczność prowadzenia dużej ilości kabli. Ponieważ część stanowiska jest ruchoma podczas użytkowania kable powinny być pospinane by nie ulec uszkodzeniom i wyglądać estetycznie. Zatem aplikacja pełni funkcję organizera trasy kablowej.

Where is your application used? In which industry?

Computer workstation (graphics, CAD, etc.) Furniture industry, office equipment

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Office environment, without pollution. Movement of parts is done at low speed.

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Originally, the elements connecting the cables on the structure were printed on a 3D printer, or the whole thing without guide elements was not very aesthetically pleasing.

Which products do you use?

- e-chains

- chainflex® cables

At which points? How did the products solve your problems?

Monitor support frame

What alternative solutions did you consider?

Yes, 3D printing

Does your application contribute to sustainability?

Certainly

Was there co-operation with igus®? If so, how was it?

Constant cooperation with the technical advisor.

How did you become aware of the vector competition?

Bilder

Award ID: 2480 Company: JC CONCEPT

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 16:17:32

- Firma: JC CONCEPT

- Ansprechpartner: Monsieur JOHAN CARBONNIER

- E-Mail: johan.carbonnier@gmail.com

- Anschrift: 13 D rue des potiers, 60650 SAINT PAUL

- Telefon: 06.47.82.71.08

- Land: France

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

barilets to counteract chills.

Where is your application used? In which industry?

automotive sector.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

We need a 300-degree angle rotation with 6 nozzles, diameter 25, loaded with water.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

increase process output improved line maintenance

Which products do you use?

- E-Chain E4.56

At which points? How did the products solve your problems?

This created an indispensable part of the process rotary joint.Rotation of 3 water circuits.

What alternative solutions did you consider?

–

Does your application contribute to sustainability?

Yes.

Was there co-operation with igus®? If so, how was it?

None

How did you become aware of the vector competition?

Award ID: 2479 Company: GODO ULTRASONIC WAVES

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 14:59:42

- Firma: GODO ULTRASONIC WAVES

- Ansprechpartner: Mr Myeongseong SEO

- E-Mail: godous@hanmail.net

- Anschrift: 1113-11 Nowon-dong 3 ga, Buk-gu,Daegu,Korea, 41555 Daegu

- Telefon: +82 10-4565-8383

- Land: Korea, Republic of

- Awareness:

- Colleagues

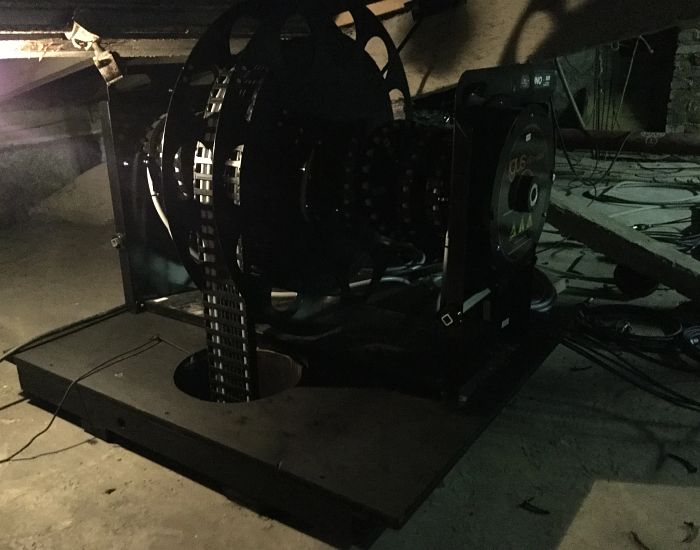

Please describe your system/machine/project. What function does your application serve?

Leak test equipment(Engine parts testing equipment)

Where is your application used? In which industry?

Automotive Parts

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Twister motion in confined spaces

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Increased product life due to stability

Which products do you use?

- Energy chain(s) TC56.12.150/650.0

At which points? How did the products solve your problems?

Increased stability and lifespan by replacing competitor chain(CP system_ helix cablevayor)

What alternative solutions did you consider?

Stability in narrow spaces

Does your application contribute to sustainability?

a little bit yes

Was there co-operation with igus®? If so, how was it?

I was impressed by the sense of responsibility for all aspects of the chain, from product selection to installation confirmation.

How did you become aware of the vector competition?

Bilder

Award ID: 2478 Company: Institute of Astrophysics and Space Sciences

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 14:50:17

- Firma: Institute of Astrophysics and Space Sciences

- Ansprechpartner: Mr Alexandre Cabral

- E-Mail: Alexandre.Cabral@ciencias.ulisboa.pt

- Anschrift: Departamento de Física – FCUL, Edifício C8 – 8.1.40, 1749-016 Lisbon

- Telefon: 351966638034

- Land: Portugal

- Awareness:

Please describe your system/machine/project. What function does your application serve?

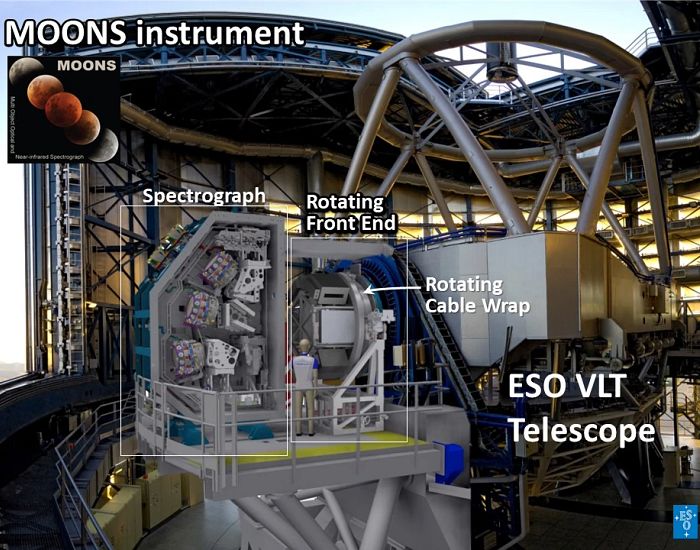

MOONS is the Multiple Object Optical and Near-infrared Spectrograph that will operate at the Nasmyth focus of the European Southern Observatorys Very Large Telescope. MOONS is an astronomical instrument designed to be a high performance and versatile survey spectrograph, with a large field of view, the size of the moon, capable of simultaneously observing 1,000 objects over the visible and near-infrared wavelength range. The instrument consists of the three sub-systems: the Rotating Front-End mounted on the VLT rotator on the Nasmyth platform, the two Triple-Arm Spectrographs and the Instrument Control.

The instrument Rotating Front End contains several modules, including a rotation cable wrap that is responsible to manage the cables and optical fibres between the Spectrograph, fixed in the telescope Nasmyth platform, and the Rotating Front End attached to the telescope that rotates during the pointing to the sky of the scientific observation. This rotation cable wrap uses a new configuration, based o a flexible solution from IGUX, the Triflex ® E-Chain Series, to guarantee that the sensible optical fibres that carry the light from the Front End to the Spectrograph do not feel any stress that could jeopardise the scientific observations.

Where is your application used? In which industry?

The application is used in astronomical instrumentation, more precisely in the focus of one of the biggest telescopes in the world, located in the Paranal mountain at the Atacama Desert in Chile, where the European Southern Observatorys Very Large Telescope is located.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

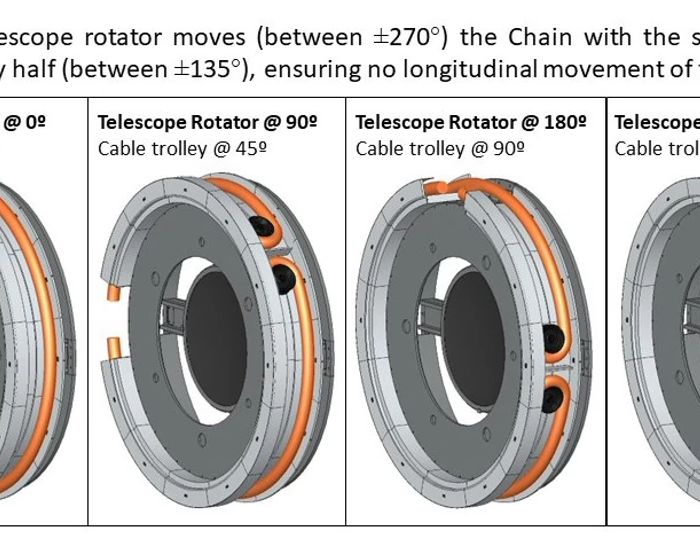

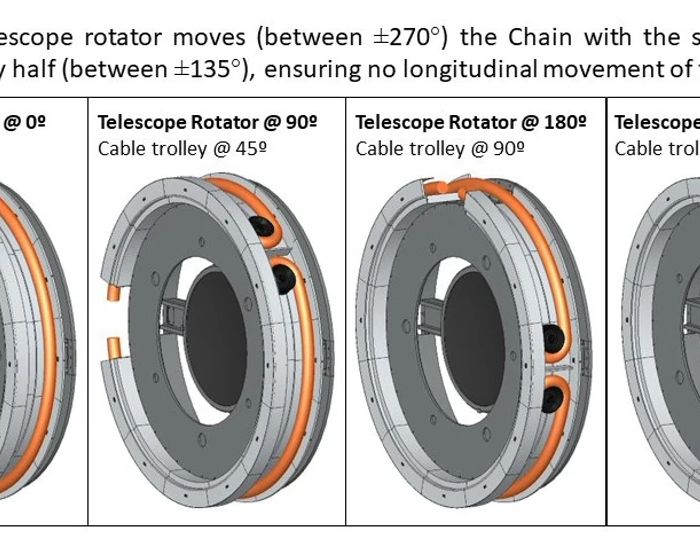

Although the ESO VLT Observatory is located in the Paranal mountain at an altitude of 2670 m resulting in peculiar environmental conditions, like very low humidity (sometimes of a few %HR) and high levels of ozone, the main challenge that was imposed to this project was related to the fibre cable management. As the part connected to the telescope has to rotate with the sky and the heavy spectrograph that receives the fibres with the astronomical light is fixe in a platform, a cable wrap is required to manage the cables and the fibres that connect both parts. The way the science fibres are moved is very critical as any push/pull force on them can cause a degradation of the optical signal (know as focal ratio degradation). Traditional rotation cable wraps are based on 2 dimensional cable chains that rotate only around one axis in a two ring configuration with two different radius of curvature. During the rotation of one of the rings, this difference (in radius of curvature) inevitably creates some slack that either pushes or pulls the cable, inducing an undesirable stress on the optical fibres. To overcome this challenge we implemented a new idea (in the area of astronomical instrumentation) with a rotation cable wrap based on a ring like shape concept that provides equal path to both halves during rotation of the Nasmyth adapter, using a 3 dimensional cable chain. This concept ensures that, during rotation, there is no longitudinal movement of the cable chain.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

In astronomical instrumentation, and in scientific application in general, cost is not the critical issue. In this application, IGUS products were fundamental to allow us to implement the new concept guaranteeing the required robustness and reliability.

Which products do you use?

- Energy chain(s) Triflex ® E-Chain Series

At which points? How did the products solve your problems?

Indeed the Triflex chain allowed us to implement the idea of a equal ring rotation cable wrap, the only way to guarantee no stress on the optical fibres.

What alternative solutions did you consider?

Due to the environmental conditions in Paranal (namely the high ozone) the use of plastic based materials is critical. Our experience from the past on other instrument at same location with IGUS chains gave us the confidence and guarantee that the material would perform as expected. Therefore, and as we found a solution with the a particular type of chain, we did not searched for other alternatives as the time spent to validate them would have a considerable impact.

Does your application contribute to sustainability?

Considering that IGUS chains use sustainable materials and due to the robustness of them that guarantees an instrument lifetime of use without replacement, it ends up being a more sustainable solution than other possibilities.

Was there co-operation with igus®? If so, how was it?

IGUS Portugal supported us in the initial search for a 3D solution and in obtaining information about the material characteristics to validate its application. This support was very useful to help on the final implemented solution.

How did you become aware of the vector competition?

Bilder

Video

Video

Video

Award ID: 2477 Company: Burgtheater GmbH Kasino

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 14:27:58

- Firma: Burgtheater GmbH Kasino

- Ansprechpartner: Herr michael steinkellner

- E-Mail: michael.steinkellner@burgtheater.at

- Anschrift: Schwarzenbergplatz 1, 1010 Wien

- Telefon: +43 664 9195830

- Land: Austria

- Awareness:

- Messe

- igus® Webseite

Bitte beschreiben Sie Ihre Anlage/ Ihre Maschine/ Ihr Projekt. Welche Funktion hat Ihre Anwendung??

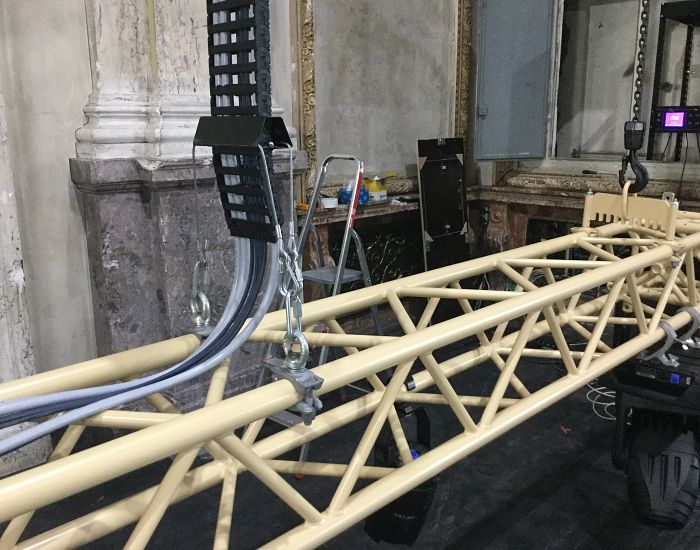

Versorgung mit Energie und Signalen in fahrbaren Traversen, für Beleuchtung und Toninfrastruktur (Intercom, Internet,…..)

Wo wird Ihre Anwendung eingesetzt? In welcher Branche?

Theater, Bühnentechnik

Wie stellen sich die Einsatz-/Umgebungsbedingungen beim Endanwender dar? Welche Herausforderungen mussten Sie dazu lösen? (Geben Sie gerne auch technische Daten zu Geschwindigkeiten, Beschleunigung und Verfahrweg an

Umgebung: Staub, Hitze/Kälte

Herausforderung: Historische, denkmalgeschützte Decke, vorhandener Durchbruch durfte nicht verändert werden. Beengte Platzverhältnisse

Kurzfristige Änderungen des Licht/Ton Verhangs können ab nun durch die automatisierte Kabelführung mit wenig Zeitaufwand und ohne zusätzlichem Personal bewerkstelligt werden.

Herausforderung: Historische, denkmalgeschützte Decke, vorhandener Durchbruch durfte nicht verändert werden. Beengte Platzverhältnisse

Kurzfristige Änderungen des Licht/Ton Verhangs können ab nun durch die automatisierte Kabelführung mit wenig Zeitaufwand und ohne zusätzlichem Personal bewerkstelligt werden.

Welche Anforderungen mussten die Energieketten und Leitungen erfüllen?

Wie konnten Sie mit den igus® Produkten die Effizienz ihrer Anwendung steigern? Konnten Sie Kosten senken?

Durch die Automatisierung konnte die Flexibilität deutlich erhöht, und die Reaktionszeit auf produktionsspezifische Wünsche deutlich reduziert werden.

Welche Produkte setzen Sie ein?

- Energiekette(n) SPHD2.850.14000.03.R.0

- Fertig konfektioniert (readycable®/ readychain®)

- Anderes E-Spool

An welchen Stellen? Wie konnten die Produkte Ihre Probleme lösen?

Traversenversorgung

Welche alternativen Lösungen kamen in Betracht?

Keine (manuelles Handling)

Gibt es einen Nachhaltigkeitsaspekt bei Ihrer Anwendung?

System funktioniert ohne zusätzlicher Energie

Gab es eine Zusammenarbeit mit igus®? Wenn ja, wie verlief diese?

Kompetente, zielgerichtete Beratung, Unterstützung vor Ort bei Inbetriebnahme

Wie sind Sie auf den vector Wettbewerb aufmerksam geworden?

Bilder

Video

Award ID: 2476 Company: DUSSAU DISTRIBUTION

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 13:59:32

- Firma: DUSSAU DISTRIBUTION

- Ansprechpartner: Monsieur Frédéric DESTRIBOS

- E-Mail: f.destribos@dusseau-distribution.com

- Anschrift: ZA ROUTE D'AIRE, 40320 PECORADE

- Telefon: 05.58.44.41.31

- Land: France

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

mulching robot

Where is your application used? In which industry?

agricultural breeding

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Dusty environment The height

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

Which products do you use?

- Cables chainflex®

>

At which points? How did the products solve your problems?

cables suspended in garlands

What alternative solutions did you consider?

a cable carrier chain

Does your application contribute to sustainability?

concept of sustainability

Was there co-operation with igus®? If so, how was it?

none

How did you become aware of the vector competition?

Award ID: 2475 Company: Nemak

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 12:16:03

- Firma: Nemak

- Ansprechpartner: Pan Krzysztof Leśniewski

- E-Mail: krzysztof.lesniewski@nemak.com

- Anschrift: Komorowicka 53, 43-300 Bielsko- Biała

- Telefon: 796173199

- Land: Poland

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

50t overhead crane carrying injection molds

Where is your application used? In which industry?

Overhead crane works in warehouse with molds, automotive industry

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

-temperature from -20 to +40 degrees Celsius -environment with oils

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

The cost was higher than the cable curtain, while it was crucial that the application was impossible to be snagged by a forklift, this was achieved with the Igus guide system

Which products do you use?

- e-chains

- chainflex® cable

- readycable® ;readychain®

At which points? How did the products solve your problems?

– the application works in the warehouse of injection molds

– the previous curtain was problematic because it snagged on the cable

– the guide solved the snagging problem

– for half a year there has not been any failure (since the guide was fixed)

– the previous curtain was problematic because it snagged on the cable

– the guide solved the snagging problem

– for half a year there has not been any failure (since the guide was fixed)

What alternative solutions did you consider?

replacement of the curtain with a new one

Does your application contribute to sustainability?

Yes.

Was there co-operation with igus®? If so, how was it?

Yes, the system was selected by our consultant Luke Cembala, along with installation, design and warranty services, we also learned about the competition from him.

How did you become aware of the vector competition?

Bilder

Award ID: 2474 Company: iziteach sarl

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 12:12:10

- Firma: iziteach sarl

- Ansprechpartner: Monsieur Franck STADELMAN

- E-Mail: contact@iziteach.eu

- Anschrift: 10 rue Paul Eluard, 91130 RIS ORANGIS

- Telefon: 06.11.82.60.09

- Land: France

- Awareness:

- Other

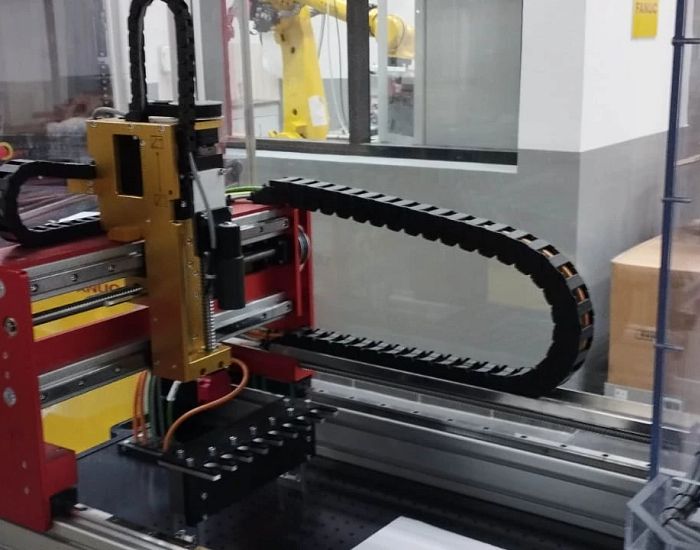

Please describe your system/machine/project. What function does your application serve?

CNC programming workstation for national education.

Where is your application used? In which industry?

high school and BTS RSA and engineering school in school.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

Small footprint. Little space to place the chain.

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

increase in service life

Which products do you use?

- E-Chain E46

At which points? How did the products solve your problems?

clutter. chain has little guidance on the ground. there's no twisting effect, chain behavior…

What alternative solutions did you consider?

None

Does your application contribute to sustainability?

–

Was there co-operation with igus®? If so, how was it?

None

How did you become aware of the vector competition?

Bilder

Award ID: 2473 Company: Nemak

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 12:08:00

- Firma: Nemak

- Ansprechpartner: Pan Krzysztof Białek

- E-Mail: krzysztof.bialek@nemak.com

- Anschrift: Komorowicka 53, 43-300 Bielsko- Biała

- Telefon: 795 461 993

- Land: Poland

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

Aluminum casting transfer station. The machine acts as an accelerated delivery of castings to machining cells

Where is your application used? In which industry?

Automotive Parts

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

-high speed-about 5m;s

-aluminum shavings

-environment with oils

-shift length 28m

-4 tracks mounted laterally to the wall in a vertical row (support 4 feeders)

-aluminum shavings

-environment with oils

-shift length 28m

-4 tracks mounted laterally to the wall in a vertical row (support 4 feeders)

What requirements did the energy chains and cables have to fulfil?

.

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

thanks to installation by Igus, it was possible to quickly install the systems during a shutdown and optimize cable life thanks to the use of PUR materials

Which products do you use?

- e-chains

- chainflex® cable

- (readycable® readychain®)

At which points? How did the products solve your problems?

the problem with the old guide, which was already worn out after many years of operation, has been solved

What alternative solutions did you consider?

none, just Igus

Does your application contribute to sustainability?

Yes. Power chain for carts / not enough recoil ( at least 2 years life )

Was there co-operation with igus®? If so, how was it?

Yes, the systems were selected for us by Mr. Lukasz Cembala, the whole thing was ordered comprehensively with installation and manufacturers warranty, and periodic inspections, I learned about Vector from Mr. Cembala

How did you become aware of the vector competition?

Bilder

Award ID: 2472 Company: SERA-GILLET SARL

Armin Gellweiler | 31. Januar 2024

Allgemeine Informationen

- Datum: 2024-01-31 11:21:56

- Firma: SERA-GILLET SARL

- Ansprechpartner: Monsieur GUILLAUME DE LUCA

- E-Mail: gdeluca@seragillet.com

- Anschrift: avenue du bois de la queille, 47400 TONNEINS

- Telefon: 05.53.64.56.26

- Land: France

- Awareness:

- Other

Please describe your system/machine/project. What function does your application serve?

-It is a cutting carriage with terminals that move on slides.

-Pantograph replacement . To power the carriage .

-Pantograph replacement . To power the carriage .

Where is your application used? In which industry?

In the sawmill sector

Primary wood processing

Highly polluted environment.

Primary wood processing

Highly polluted environment.

What are the environmental conditions at the end user’s location? What challenges did you have to overcome to adapt to those conditions? (Feel free to provide technical data on speeds, acceleration, and travel distance).

the application has simplified the use of wood cutting.

What requirements did the energy chains and cables have to fulfil?

How were you able to increase the efficiency of your application with the igus® products? Have you been able to reduce costs?

It saved money, both financially and in terms of assembly.

Which products do you use?

- E-Chain 14340

At which points? How did the products solve your problems?

by their simplicity.

What alternative solutions did you consider?

Pantograph. More complicated and more expensive.

Does your application contribute to sustainability?

Yes. Power chain for carts / not enough recoil ( at least 2 years life )

Was there co-operation with igus®? If so, how was it?

configuration with Mr RICHELcomplicated environment Yes, it went well.